Numerous companies are gaining efficiencies and sustainable savings by using shared service centers, and outsourcing solutions for back-office functions. They are now looking to expand that model to other functions. Supply chain, which was traditionally decentralized across sales offices, plants and distribution sites, is emerging as an area of focus for value creation and cost reduction through migration to global business service (GBS) operations.

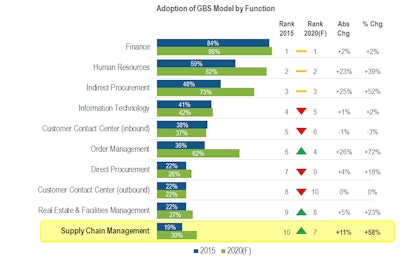

While the presence of enterprise-wide supply chain activities is still limited, companies with existing GBS operations expect a 58 percent increase in the adoption of supply chain processes into their GBS by 2020. In fact, supply chain processes are expected to be included in nearly a third of existing GBS operations by 2020 (see Figure 1).

Mature, global companies are beginning to move selected supply chain activities from the business into a centralized structure, starting with supply chain planning and delivery activities. In The Hackett Group’s “2016 GBS Performance Study,” 20 percent of existing GBS operations now include supply chain activities in their scope of services. The Hackett Group expects GBS operations to incorporate the supply chain processes shown in Figure 2 over time.

By migrating supply chain activities to the GBS, companies can realize several distinct sources of value:

- Improved operational performance.

- Cost savings.

- Better customer service.

- Higher employee satisfaction.

- More effective risk management.

To achieve these benefits, companies are leveraging common practices to move their supply chain to the GBS. In particular, these companies are focusing on improving service design, service partnering, and organization design and governance with the following practices:

- Development of centers of excellence (COEs) for advanced knowledge-centric processes that are cross-regional in nature (e.g., supply chain strategy and trade compliance).

- Creation of centralized process owners to manage continued initiatives for process improvement.

- Process standardization to facilitate the implementation of a single global technology platform and advanced supply chain tools (e.g., analytics, planning, warehouse management and transportation systems).

- Creation of enterprise-wide supply chain roles to drive global efficiencies and increased collaboration.

- Migration of selected activities to third-party providers, such as inbound and outbound transportation, reverse logistics and manufacturing operations.

Realizing the advanced capabilities and the benefits associated with a GBS model takes dedicated, committed resources. And perhaps more important, it takes time. Each company’s journey to GBS implementation varies significantly based on the specific processes being migrated, the level of internal acceptance and readiness for centralization, and potential benefits to be achieved. Nonetheless, companies are seeing the benefits of this new business model and are gearing up to make supply chain the next area of focus for their GBS operations.

To read the complete research described, please click here.