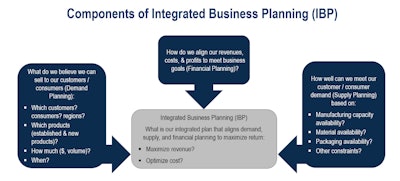

Many companies still struggle with executing a strategic integrated business planning (IBP) process that effectively integrates demand planning, supply planning and financial planning. Most simply put, the process should drive decisions on how to best meet demand (customer/consumer sales for existing and new products) within supply constraints in order to optimize financial return. Yet, answers to the questions of each planning component of IBP can be dramatically different and lead to very different results if addressed in silos vs. in an integrated fashion.

Put more bluntly, companies that successfully execute IBP achieve greater operational and financial benefits than those that do not. A key requirement for that success is collaboration, including a disciplined, repeatable process that drives integrated decision-making and a balanced scorecard for performance measurement.

Based on our experience, we at The Hackett Group believe unlocking IBP can deliver the following competitive advantages and benefits:

- Visibility into the financial implications of decisions and actions related to demand and supply.

- Significant cost improvements driven by a more efficient and effective supply chain.

- Improved top-line revenue growth.

- Inventory deployment improvements (e.g., the right product in the right place at the right time), which reduce excess deployment costs, based on customer demand.

- Increased customer satisfaction as a result of more accurate demand planning and inventory availability, which reduce out-of-stock and back-order issues.

However, with all of this evidence that implementing IBP leads to important benefits in an increasingly competitive environment, why do many companies continue to miss out on the potential rewards of IBP?

We believe there are five keys (in the form of questions) that companies can use to open the doors to an effective and efficient IBP process. The first two questions deal with the marketplace and competitive environment in which the business operates, while the final three questions help assess internal improvement opportunities based on best practices for process, people, data/systems and technology capabilities tied to IBP.

1. What Are the Big-Picture IBP Trends in the Marketplace?

Here are three examples of what leading companies are doing:

- Streamlining annual planning and budgeting processes.

- Balancing scorecards with cascading metrics.

- Unifying data models and better integrating technology platforms to support advanced planning and analytic capabilities.

2. How Do our Supply Chain Costs and Metrics Compare to Other Companies?

Benchmarking can serve as a useful tool for measuring performance against the competition. Armed with valuable key performance metrics for cost, process and resources, supply chain leaders are equipped to make critical decisions and address areas of opportunity.

As an example, the metric demand/supply planning costs per $1,000 in revenue is an excellent indicator of overall efficiency.

3. Are Optimal Planning Processes in Place throughout the Organization?

Establishing a best-in-class IBP process is the foundation for maximizing the efficiency and effectiveness of any organization. Example best practices include:

- IBP goals and objectives are clear and well understood.

- The IBP process evaluates gap resolution and business optimization options.

- Materials and reports supporting IBP are exception-based.

4. Do We Have the Right People at All Levels of the Organization, to Own the Plan, Make Decisions and Ultimately Be Held Accountable for the Plan’s Execution?

Equally as important as the right processes is having the right organizational talent and accountability mechanisms in place. Example best practices include:

- Adequately staffed resources with the required knowledge and skills.

- Clear ownership and accountability.

- The discipline to adhere to decisions made as part of the IBP process.

5. Are We Equipped with the Appropriate Technology (Tools and Systems) to Fully Support Integrated Business?

To enhance supply chain technology capabilities that both support and optimize the integrated business planning process, best-in-class organizations successfully employ supply chain systems and tools to maximize their IBP process. Importantly, the firm must have the tools and systems needed to bring together and reconcile demand, supply, and financial plans in order to identify gaps and imbalances.