As long as there are rodents and other pests in the world, the battle to thwart their efforts to infiltrate warehouses and distribution centers (DCs) will continue.

For example, in February 2022, a national discount store chain announced the closure of more than 400 retail locations as well as a voluntary product recall due to rodent infestation at one of the company's DCs in Arkansas. These actions followed an FDA inspection that found both live and more than 1,000 dead rodents, rodent excreta, as well as evidence of rodent gnawing and nesting.

And in the spring of 2017, an FDA inspection at a food warehouse in St. Paul, Minn., involved the seizure of $73,000 worth of food due to the facility being infested by rodents, live birds and insects. At this particular facility, FDA inspectors discovered dead rodents in food storage areas, evidence of rodent excreta, food containers on which the rodents gnawed as well as rodent nesting material between food pallets.

A highly serious issue that shares a common element

While an unpleasant topic, rodent infestation and the dire need for effective pest management — especially in food-related warehouses, DCs, as well as food manufacturing and packaging facilities — can never be taken too seriously.

Factor in as well the risk of significant product loss as a result of improper pest management; consider that if product loss is maintained at even just one percent, shipping $10,000,000 out of a facility in one year will add up to $100,000 in loss. Investing a small amount of capital to consistently reduce product loss by 50% could easily amount to a $50,000 return to the bottom line.

As such facilities undergo government-sponsored FDA and USDA inspection audits, in addition to those from third-party inspection organizations such as AIB International and SQF Institute (SQFI), there is one point of risk for infestation that all warehouses and DC operations have in common no matter how large: the loading dock.

Whether a facility has one or even hundreds of loading docks, they remain one of the most suspect gateways to rodent infestation. And for inspection audits, loading docks are some of the hardest areas for which to achieve compliance as food companies of all sizes and related businesses have a high degree of vested interest in ensuring that their products are safe at all times.

Done properly, effective pest management and control can even have a big impact on inspection audit scores that various facilities often openly display in their reception areas as a “badge of honor.”

Loading docks are a unique challenge

Because loading docks present the largest openings in any warehouse or DC, they’re a unique challenge and a prime target for pest infiltration. The main reason is the gap that exists between the loading dock pit and the dock leveler. Although only about an inch in width on each side of a leveler, such gaps that are left open are prime entry points for rodents and other pests to penetrate a facility. Mice can even penetrate openings as small as one-quarter inch.

Liquid and solid food product spillage during unloading and loading, as well as broken pallets, all play a role in contributing to attracting rodents along with ants and other insects. As a standard preventative measure, loading docks have relied on brush barriers that are affixed to levelers. However, over time, such brush barriers can become damaged leaving gaps for rodents to penetrate.

In addition, weather seals on dock doors can eventually show signs of wear and tear and weather seals are prone to damage from rodents, especially if they become coated in any kind of liquid food product. Brush example from APS Resource.APS Resource

Brush example from APS Resource.APS Resource

Looking for light penetration

During the audit process around loading docks, inspectors routinely look for any evidence of light penetration and/or gaps around levelers and doors. Again, worn leveler brush with missing sections is notorious for light penetration with rodent infiltration as the unwanted outcome.

When put on notice about a pending audit, and while rushing to get ahead of inspectors to repair any damage to their pest control measures, warehouses and DCs often incur much higher costs due to overnight delivery charges and other higher expenses. Even average or satisfactory audit scores are unacceptable to brand-name food companies. They know all too well that the highest audit scores for themselves and their suppliers translate into higher product pricing and better customer retention. Conversely, poor audit results can lead to negative effects on product pricing, and as shown earlier, negative media coverage.

Viable solutions for effective pest management

The good news for warehouses, DCs, food manufacturers and their suppliers, is that there are viable solutions available to prevent rodent infestation at the loading dock.

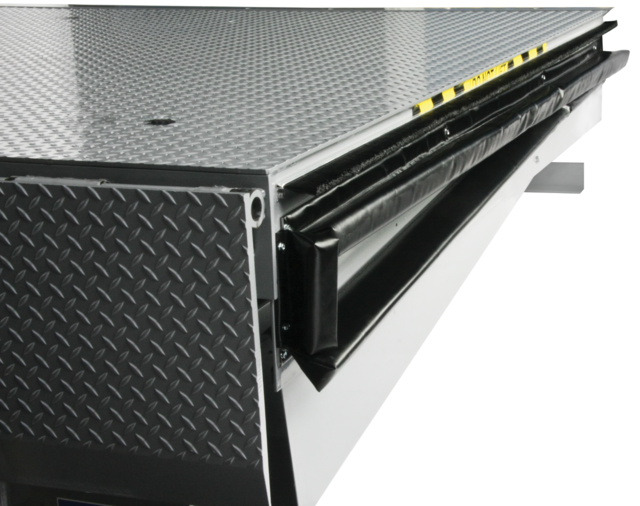

In addition to the standard brush approach to sealing gaps in dock levelers, facilities can go one step better by installing a vinyl-encapsulated open-cell foam seal.

This triangular-shaped seal, designed to minimize wear as it raises and lowers in the dock pit, offers enhanced protection against rodent infestation by forming a compression seal between the concrete pit and the leveler. This results in a very tight seal with no gaps for light or air for rodents to penetrate. Even if a leveler’s companion brush seal becomes damaged, the foam seal below the brush will still help to fill any gaps.

Leveler example from APS Resource.APS Resource

Leveler example from APS Resource.APS Resource

A leveler’s tight foam seal also provides an added benefit beyond pest prevention: it will also help to eliminate the mass flow of air, minimizing the transfer of energy in and out of a facility along with associated energy loss, especially for cold storage facilities. The result can be a one-year ROI on energy cost savings. And depending on the location of cold storage facilities, a strong ROI can be achieved in as little as six months.

Keep in mind too that dock levelers have more than just gaps to seal around their perimeter to prevent rodent infiltration. Closing up any chain pull areas, installation plug openings, and gaps between transition plates are also necessary to keep pests out.

As for dock doors, seals with a rubber membrane sandwiched between a layer of brush on either side that are mounted to the door jamb at a 45-degree angle means that even if any brush is damaged or comes loose, the rubber membrane will still block any light penetration.

Preparation and prevention are key

As you can see, concerning loading docks and pest management, preparation is key while the famous idiom “an ounce of prevention is worth a pound of cure” rings as true as ever.

By ensuring that loading docks are properly maintained using the right pest management measures, warehouses, DCs, food manufacturing operations and packaging support facilities alike can easily realize the benefits of reducing audit preparation costs as well as increasing their audit scores as they apply to the loading dock area. That’s a win-win for everyone involved.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)