Doing things faster, better, and cheaper is the never-ending theme for the supply chain. Rising tariffs and trade shifts are putting supply chains under more pressure. In response, many businesses are pursuing strategies like near-shoring, alternative shipping routes and new sourcing locations. While these geographic adjustments are helpful, they come with other short-term costs, and they only address a small section of the complete supply chain network.

Forward-looking organizations understand they need to go beyond just geography. They are increasingly leveraging technology, specifically AIoT, which integrates artificial intelligence (AI) with the Internet of Things (IoT). When applied strategically, AIoT can transform warehouses into smarter, more efficient, and more agile operations, enabling businesses to stay ahead of disruptions.

The warehouse’s role in the supply chain

The products we use daily, from smartphones to groceries, rely on intricate supply chains. Think about big-box companies managing millions of products and customer orders daily. They rely on a vast network of suppliers, logistics providers and software systems. As if that weren’t complex enough, layering on global tariffs and trade disruptions exponentially increases the challenge.

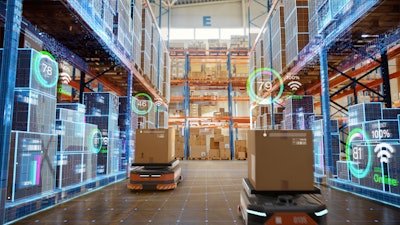

Within this intricate web, warehouses are a linchpin. This is where hands-on work occurs – managing receiving, storing, accurately picking, and ensuring timely shipping of goods. Today’s high-order volumes and next-day delivery expectations demand both automation and precision. IoT devices like advanced barcode scanners, sensors, cameras, smart shelves, robots and drones support this process, generating real-time data that feeds warehouse management systems (WMS).

This data-rich environment positions warehouses as prime candidates for AI-driven transformation.

Understanding AIoT in context

Traditional IoT implementations collect massive amounts of data but often lack the intelligence to act on it. AIoT bridges that gap by merging IoT’s real-time sensing with AI’s ability to analyze, learn and predict. This combination empowers warehouses to respond proactively to challenges like trade disruptions, rather than react after the fact.

How AIoT drives efficiency

Traditionally, reacting to tariff changes meant scrambling to adjust supply chains, renegotiate contracts, or simply absorb costs after new policies were implemented. However, AIoT offers a fundamental shift toward proactive management. Beyond helping to navigate tariffs, AIoT delivers substantial efficiency improvements that fundamentally strengthen overall warehouse performance.

So, how does this proactive management manifest? AIoT enables this shift by providing capabilities in several key areas:

Automation and robotics: AI-powered robots such as autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and advanced driver assistance (ADAS)-equipped systems, paired with wearable IoT and human workers, are transforming warehouse operations at unprecedented speed.

Forecasting and prediction: AI algorithms can monitor forklifts, conveyors, and other assets in real time, spotting early signs of wear or failure. This minimizes costly downtime and increases operational flexibility.

Computer vision: Integrated camera systems analyze workflows, flag safety risks, and detect suspicious activity like cargo tampering without manual oversight. They can also suggest layout optimization for better space use.

Wearable IoT: Devices worn by workers can track vital safety metrics and monitor for fatigue, allowing managers to intervene proactively to prevent accidents and maintain productivity levels.

Digital twins: Virtual replicas of the warehouse allow simulations and testing of new layouts, flows, or contingency plans. As AI models learn from real-world data, these digital twins become more accurate and insightful.

Smart energy use: AIoT-enabled battery packs, lighting, and climate systems respond to usage patterns, cutting energy waste much like smart home systems do in residential settings.

Data integration and insight: AIoT harmonizes sensor, image, and operational data with supply chain systems, improving visibility. It can also surface compliance risks or automate documentation.

Implementation strategies for maximum benefit

While AIoT offers tremendous potential, successful implementation requires thoughtful planning and a strategic approach.

Focus on these strategies for maximum benefit:

- Start with high-value use cases: Don’t try to overhaul everything at once. Instead, start with pain points where AIoT can show fast results, like optimizing inventory levels, implementing predictive maintenance for critical equipment, or enhancing energy management.

- Build an open, scalable technology foundation: Choose technology platforms designed for integration and scalability. Open APIs, cloud-based architectures, and modular systems allow for incremental expansion as needs evolve.

- Invest in data quality: Remember, AIoT systems are only as effective as the data they receive. To ensure accuracy, regularly calibrate sensors, standardize data formats across systems and enforce robust data governance.

- Empower your team with AIoT: AIoT works best when paired with skilled people. Invest in training so workers can collaborate with smart systems, interpret insights and offer feedback that improves performance.

Final thoughts

While external factors such as trade policies remain beyond direct corporate control, the efficiency and resilience of your warehouse operations are firmly within your sphere of influence. AIoT provides a proactive path to emerge stronger as an industry leader.

By integrating intelligent automation with human expertise, AIoT transforms warehouses into connected, adaptive environments. These smart systems improve performance, boost agility and future-proof operations against uncertainty.