Do you know how well your supply chain technology suite is helping your organization reduce costs, drive efficiency and enable effective decision-making across every element of the supply chain? As organizations grow and mature, efficiently and strategically managing the organization’s supply chain applications across the technology suite only grows in importance—the alternative often leads to disparate, nonintegrated systems that cost more to maintain, and hinder transparency and decision-making.

Before an organization can begin maximizing the benefits that can come from supply chain technologies, it must first truly understand how broad of a role supply chain technologies play across the organization. Figure 1 portrays the touch points that supply chain applications have across the organization.

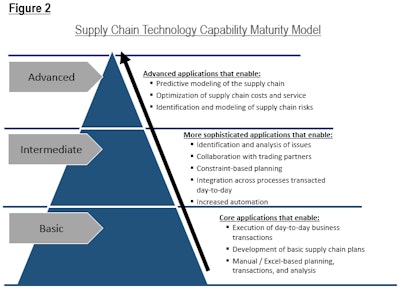

Once a holistic understanding of the many components across the organization that are encompassed by supply chain technologies is developed, the next step is to understand where your organization falls within the capability maturity model. Figure 2 highlights the levels of supply chain technology maturity and some of their corresponding attributes.

Understanding at what level your organization is operating based on the capability maturity model is a great place to start to understand how much room your organization has for improvement relative to the spectrum of existing supply chain technologies. Further understanding of where those areas of improvement are, specific to your organization, is the next step. Below is a small sampling of areas where we often see room for improvement:

- Systems costs for performing warehouse operations.

- Inventory obsolescence rates.

- Systems costs for performing outbound transportation.

- On-time delivery metrics.

Identifying areas for improvement and implementing those improvements is one thing, but implementing improvements that are sustainable is another. All too often, technology solutions are implemented without proper attention paid to supporting best practices that take into account processes and people. When this happens, the benefits achieved are often less than what could be realized had the proper governance, metrics, training, etc. been identified and implemented simultaneously to the technology component. It is critical that any supply chain technology improvements are implemented in parallel to supporting best practices to ensure initiatives yield the maximum benefit and truly advances an organization’s capabilities.

At the executive level, we found that best-in-class organizations not only have an understanding of the importance of their supply chain technology suite, but have a strategy for managing the suite’s application and improvement. As a result, best-in-class companies have thoughtful answers to the below questions—try to answer these questions for yourself to see where your organization may benefit from some additional planning:

- How can supply chain technology support revenue growth and cost improvement initiatives?

- How do we achieve better results from our current technology?

- How can we improve supply chain decision-making to reduce risk and improve agility?

- Where are other companies investing in technology to improve the efficiency and effectiveness of their supply chain?

Supply chain technologies can be very powerful enablers of efficiencies for organizations if deployed strategically and deliberately. We see best-in-class supply chain organizations enjoy numerous competitive advantages to their peers that translate to lower costs, more efficient operations and better decision-making. How does your supply chain organization compare?

The complete research described here is available, with registration, here. Download the full report from The Hackett Group to learn more about trends, best practices and metrics that help organizations optimize their supply chains by using advanced analytics.