Automation is no longer optional for logistics—it is essential to keep our supply chains moving in the face of disruption. Ever since the COVID-19 pandemic, we’ve experienced a steady stream of supply chain disruptions due to economic uncertainty, shifting trade policies, climate events, and other factors. The world has learned the hard way that adaptability in logistics is not optional; it’s essential.

Adopting automation and robotics has taken center stage as a means to minimize supply chain disruptions. Yet, there are leaders in logistics and transportation waiting for the perfect robots before integrating them into operations. This is a common misconception. The goal with robots isn’t perfection; it’s progress. The key is to deploy robots that provide real value now, while keeping humans in the loop to manage exceptions, solve problems creatively, and ensure operations remain agile as the business evolves.

Robots deliver value now, even if they’re not perfect

Robots have traditionally excelled at repetitive, standardized tasks in static environments, where the situations robots face are uniform. Take, for example, production lines, with robots repeating the same stitch, weld, or bolt tasks over and over. These robots rarely need human help and typically stay in one place.

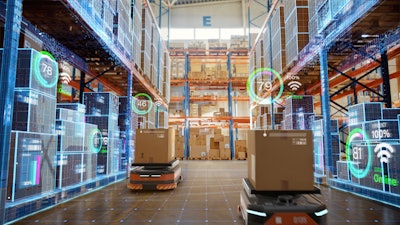

More recently, robots, including autonomous vehicles (AVs), have been deployed in diverse and dynamic environments like homes, sidewalks, and warehouses, where they must navigate complex spaces and occasionally rely on human assistance.

This is already playing out in logistics and transportation today:

● Autonomous yard trucks move trailers efficiently through distribution yards, reducing congestion, idle time, and human exposure to dangerous fumes and 80,000-pound equipment. If these robots encounter unexpected obstacles, they may call on humans for assistance. This human-robot partnership ensures operations run smoothly for warehouse personnel and truck drivers moving shipments on the road.

● Picking and sorting robots streamline fulfillment operations, working continuously without fatigue. However, when an item is misplaced, damaged, or unfamiliar to the system, humans are necessary for troubleshooting, re-routing, or ensuring proper handling.

● Automated storage and retrieval robots enhance inventory accuracy, reduce retrieval time, and support high-volume order fulfillment. If the system encounters a jam, a missing SKU, or an unexpected inventory issue, human intervention ensures that the problem is resolved quickly and workflows resume without disruption.

Even with occasional help from humans, operations can derive measurable value from these robots by enhancing safety, reducing downtime, and freeing employees to focus on more complex, higher-value tasks. Rather than holding out for robots that can handle every possible scenario, companies should deploy them where they excel.

Clear roles and responsibilities for human-robot collaboration

To unlock the full potential of robots in dynamic, variable environments, there are three “must haves.” First, there must be repetitive, routine tasks that the robot can reliably perform day in and day out. Second, the robot must be able to safely navigate its environment to perform these tasks. Finally, a human must be in the loop to handle a small number of complex or unpredictable situations.

In short, the robotic solution handles the vast majority of routine tasks, providing a steady baseload capacity, while humans handle the exceptions. Humans have problem-solving and physical capabilities necessary to handle edge cases where robots are involved. As robots and humans work together, both will adapt—robots will learn to operate in increasingly dynamic environments, and humans will learn to optimize their workflows alongside robots. The pace of this learning curve will continue to accelerate with the latest advances in generative AI and reinforcement learning models, plus the speeds at which they can be trained and deployed.

The future of robots and humans working together

Accelerated by AI, robots will evolve to handle more complex and diverse situations. Rather than waiting for perfection, businesses should integrate AI-driven robotic and autonomous solutions now to unlock both immediate gains and long-term potential. While robots continue to learn and improve, humans provide the critical oversight and problem-solving that make today’s deployments reliable and scalable.

This collaborative model not only improves efficiency and safety but also creates a new wave of high-quality jobs—like field support technicians, certified installers, and remote operations specialists—that can boost employee satisfaction, engagement, and retention. For example, in distribution yards, autonomous systems like Outrider’s free up site managers to focus on workforce development and operational strategy, rather than day-to-day trailer movement and routinely hiring and onboarding employees due to high turnover rates in the industry.

Fully integrated robotic systems like these are designed to scale with evolving capabilities, working safely alongside human teams today while continuously learning to take on more complex tasks over time.

Logistics and transportation leaders must prioritize the practical adoption of robotics now, rather than waiting for perfection. Companies that adopt automation early will gain a competitive edge—lowering costs, improving operational resilience and safety, and future-proofing their workforce. The future of logistics and transportation isn’t about replacing humans but enabling them to work smarter alongside automation, creating a more sustainable and scalable supply chain.