If a company wants to excel, it must be great in its largest cost area. Yet, fewer than 10 percent of companies leverage supply management excellence to deliver and sustain a competitive advantage.

A recent report, “The Assessment of Excellence in Procurement 2017,” corroborated by companion A.T. Kearney studies, shows that while many companies have made significant progress, there is still much work to be done. Based on their effectiveness in addressing external spend, the report divides companies into four distinct groups: Leaders (7 percent) demonstrate excellent supply management capabilities and stellar performance; Aspirants (11 percent) produce solid results and are making significant strides toward becoming leaders; The Pack (55 percent), while adding value, are not transforming fast enough; Strugglers (27 percent) barely cover their costs, let alone add value.

Leaders Drive More Value

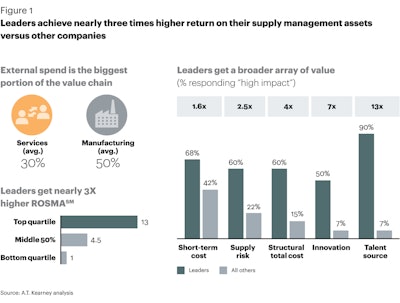

If a company is going to excel, it needs to be great at external spend, which represents, on average, 30 percent of a service company’s revenue and 50 percent or more of a manufacturing company’s revenue. According to the report, Leaders achieve nearly three times higher return on their supply management assets (ROSMASM) score versus other companies, and they also deliver a broader array of value (see Figure 1).

Additionally, Leaders are two and a half times more likely to deliver a high impact on managing supply risk, four times more likely on reducing structural total cost of ownership (TCO), seven times more likely on driving innovation, and 13 times more likely on positioning their supply management organization to be a talent source for the rest of the enterprise.

Looking ahead, global shifts demand even more from supply management. The recent rise of populism and a greater focus on sustainability are forcing all companies to rethink their bias from globalism to localism, and may force major shifts in the footprint of their supply base. Disruptive technologies are reshaping processes, changing business models, and impacting cost structures. Advanced analytics allows companies to harness the complexity of big data, uncover hidden patterns, and exploit the resulting insights. Artificial intelligence is being applied to a range of activities from automatically classifying spend data to analyzing contracts, to evaluating sourcing and negotiating strategies. Robotic process automation is reducing cost structures and improving consistency and compliance. Additionally, M&A activity continues to grow. These mergers increasingly rely on cost synergies to de-risk their economics which positions supply management as the merger money machine.

These trends accelerate the need for CPOs to manage change and deliver true competitive advantage from the supply management component of their value chain. Understanding how Leaders succeed and transform themselves provides valuable insights for all companies.

Formula for Success in Supply Management

Leaders attain and sustain their effectiveness by following a three-part success formula to achieve excellence (see Figure 2).

Team excellence provides a catalyst by which supply management aligns with and helps shape the strategic goals of the company. It also enables sustainable results through process design and implementation, technology investments, talent development, and performance management.

supply management is a business partner in leading companies. More than 90 percent of leaders report to the C-level. They are three times more likely to have high involvement and three times more likely to have high impact in key business processes.

Leaders transform their supply management operating models and organizations to focus on strategic value-creating activities. To attract and retain their strategic talent, Leaders provide entrepreneurial opportunities, invest in skill development, and are three times more likely to focus on developing a leading “brand” for their procurement organizations.

Category excellence is the most powerful cost reduction lever generating more than 70 percent of procurement value. Additionally, it provides key insights about supply markets that help to shape the company’s business strategy.

Nearly every CPO knows how to negotiate with incumbents and do competitive bidding, but Leaders are nearly three times more likely to apply a tailored set of methods to deliver value based on a category’s supply and demand power balance. Leaders inform the strategic direction of the company by developing long-term plans for important categories, where they gain key business insights about supply markets.

Supplier excellence ensures that suppliers comply with contractual requirements and, more importantly, that the company reduces overall supply risk and gains competitive advantage through more rapid and impactful innovation from supply markets. Leaders actively monetize the full supplier life cycle. While most companies have processes for sourcing, selecting and contracting with suppliers, Leaders are more likely to have focused initiatives to proactively manage their supply base footprint.

Once suppliers are onboarded, Leaders have higher compliance to negotiated contracts. While the requisition to pay (R2P) process is typically the most mature process for all companies, it is well-established and highly efficient for leaders.

The third part of the life cycle is to focus on joint improvement. Here, Leaders create differentiated and highly effective programs for strategic versus mainstream suppliers, while 20 percent of other companies do not even have a program for mainstream suppliers.

Lifting the State of Supply Management

To lift the overall state of supply management, every company needs to mobilize for success regardless of where they lie along the spectrum.

Strugglers need to focus on delivering results today by using strategic sourcing and compliance to deliver major cost savings, or risk being marginalized. The Pack need to establish credibility as respected contributors and continue to add value. They need to assess their capabilities

against the success formula and establish priorities. Aspirants need to build the environment within the company that enables success— going from good to great. Leaders must ensure that the supply management team understands and aligns with long-term goals and strategies for supply management; challenges the team to provide a continuous stream of value to the company; and continues to attract and develop a highly talented, high performing team.

The CPO-CFO partnership is crucial to building a world-class supply management capability. The CFO and CPO share the unique capability of being able to see into and influence cross-enterprise activity and supplier spending. Working together, they can effectively manage the drivers behind this cost and make a significant impact on the P&L statement.