After years of wavering negotiations, 150 world leaders met in Paris to address issues facing the global environment due to climate change, with the hopes of achieving a legally binding agreement on curbing emissions. As nations discuss strategies for controlling global temperatures, leading manufacturers are independently stepping up actions to reduce the environmental impact of their products and are starting to look beyond what are considered traditional sustainability objectives to make an even bigger difference.

As one of the largest consumer goods companies in the world, Unilever is a prominent example. By 2020, Unilever’s ambitious goal is to halve its environmental footprint, improve the health of 1 billion people and enhance livelihoods for millions—all while doubling its sales. In The New York Times, Paul Polman, CEO of Unilever, recently acknowledged this is a giant task that will not be easy to achieve. The endgame involves cutting the lifecycle impact of products and finding ways to serve more people with fewer resources.

This means rethinking how we feed and provide goods to a rapidly growing population. Our generation stands at the edge of the largest growth opportunity in history, with global demand expected to double by 2050. One thing is clear—business as usual will not get us there. The current global population of 7 billion is already consuming resources at one-and-a-half times the capacity of the earth. Traditional practices to produce and distribute goods cannot address the needs of another 2 billion people and the rise in demand from the ascendency of emerging countries like India. A series of step-changes in efficiency in several parts of the global supply chain is required.

Many such shifts to reduce the environmental lifecycle impact of products are underway. Sustainable farming, land stewardship and watershed management practices are changing the environmental impact of commodities and food production; products are being reformulated to use less water by consumers; manufacturing plans are increasingly powered by renewable energy; and shifts in fuel and transportation modes lower emissions from distribution. A relative newcomer to the scene are programs designed to control demand volatility. Though not traditionally seen as a sustainability initiative, controlling demand volatility may represent the single largest opportunity for companies to reduce the lifecycle footprint of its products.

Why is this? Volatility drives much of the inefficiency in the modern supply chain. If manufacturers knew exactly what customers would order, that is precisely what they would build. Unfortunately, the majority of goods purchased by consumers are make-to-stock. Since products must be ready to deliver when customers order, companies must carry extra stock to serve as an insurance policy. There is a direct correlation: The higher the demand volatility, the more inventory that is required to protect customer service.

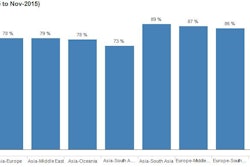

While quarterly financial forecasts can be 90 percent accurate, weekly item-level accuracy for supply chain execution is typically 50 percent or less for consumer packaged goods companies. This means that, on a forecast of 100 cases, half of the time, shipments are between 50 and 150 cases; the other half of the time, it is outside that range. With this level of uncertainty, ensuring service commitments requires a lot of excess inventory.

Historically, accurate forecasting was a challenge. Fortunately, advances in technology to leverage big data and sense demand—akin to how financial trading systems use big data for automated trading—is changing this, allowing make-to-stock manufacturers to better predict demand and permanently reduce inventory levels.

When it comes to the link between inventory and sustainability, the question on everyone’s mind is how does excess stock due to uncertainty hurt your environmental footprint? It is not intuitively obvious like switching to solar to replace dirty electrons with clean ones, so it is often overlooked. After all, safety stock held as insurance against volatility is eventually sold for use by consumers (aside from waste stemming from spoilage, damage or theft). However, once sold, it must be replenished as not to jeopardize customer service. The net result is a fixed stock overhead required to run your business, simply due to demand uncertainty.

The extra stock carried to protect against uncertainty creates an enormous inefficiency within the supply chain. For consumer goods companies, this represents roughly 25 percent of all inventory. Furthermore, it is coupled to sales—if your business doubles, so does the amount of safety stock. There is roughly $10 trillion in global inventory or approximately one year’s worth of goods that were produced before they are needed.

By controlling volatility, companies can permanently cut this fixed overhead and serve more people with the same amount of production.

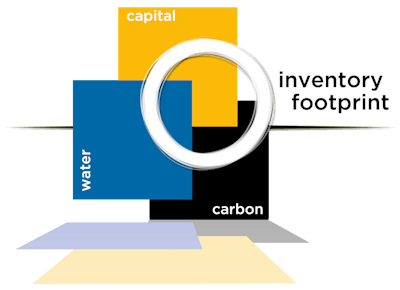

Fortunately, for executives with sustainability goals, it turns out that permanently reducing the amount of inventory required to run their business is the environmental equivalent of a jackpot multiplier. In addition to eliminating emissions and water required to manufacture, transport and store this extra stock, it also eliminates the environmental footprint of all of the underlying raw materials that go into making the products. This is what makes controlling volatility so impactful. Depending on the product, the embedded carbon and water in raw materials can range between 20 and 99 percent of the product lifecycle footprint. Going back to the jackpot analogy, this provides a 20 to 100 times bonus multiplier compared to the emissions savings relating to the manufacturing, transportation and storage of these goods.

To give a sense of how significant these savings can be, consider the case study of a global consumer goods company using demand sensing technology to improve forecast accuracy. Over an 8-year period, this company cut 25 days of inventory. In addition to freeing roughly $2 billion in cash and improving the return on capital, permanently reducing this inventory from the supply chain cut 1.15 million metric tons of CO2 and 50 million cubic meters of water. To put this in perspective, the carbon savings for all other sustainability initiatives since 2008 at this company was 1 million metric tons of CO2.

With the United Nations Climate Change Conference in Paris, the signs are positive. Along with the new sense of optimism, I am encouraged that supply chain and sustainability professionals are starting to view inventory as more than just piles of cash, but also piles of carbon and water, and recognize the importance of controlling demand volatility as an essential tool to serve more people in an increasingly resource-constrained world.