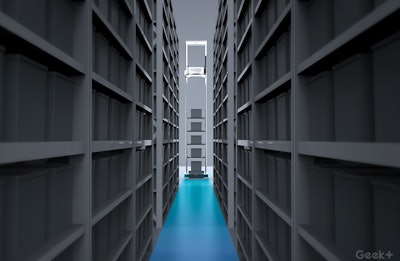

Geek+ announces the release of the world’s first extended-depth bin-to-person robot, the AMR solution with the strongest single-layer storage capability to date. The C200M operates on narrow aisles and its extended arms reach new storage depth, saving up to 50% of warehouse space and significantly reducing warehouse rental costs. The robot also reaches new heights, covering storage from 0,215 meters to up to 5 meters. The storage capacity of the warehouse increases by 2.5 times to that of a manual warehouse.

With warehouse rental costs on the rise everywhere, accounting for over 40% of overall operating costs, the C200M can effectively ease cost pressures by compressing the warehouse area and improving storage efficiency. In addition, the robot uses the Geek+ intelligent system, with AI algorithms covering order analysis and robot scheduling to make entire warehouse operations more flexible, scalable and efficient.

“Our R&D team is constantly pushing boundaries to develop the most advanced AMRs on the market, bringing our customers significant added value and transforming logistics operations. Since its launch in 2015, the Geek+ picking system has led the industry with real and visible business returns for our customers. The new C200M picking robot will bring customers even more value by reducing warehouse rental costs and improving storage capacity to propel long-term development of enterprises and realize flexible, smart upgrades,” Yong Zheng, founder and CEO of Geek+ says.

C200M: stronger storage capacity maximizes ROI on warehouse rental

- Aisle area cut in half: the C200M utilizes a 1.4m telescopic fork to access two rows of containers from one side of the shelf and operates on 1m wide aisles

- Extended robot cargo storage range: as low as 0.215 meters and up to 5 meters

- Multi-level deployment using mezzanines, as part of RoboShuttle system

Geek+ RoboShuttle: flexible & scalable warehouse operations to respond to market demands and seamlessly adjust to business needs

- Robots can be added at any time to respond to business fluctuations.

- The malfunction of a single robot does not affect overall operations and the system has an ultra-high fault tolerance rate, ensuring the sustainability of the supply chain and preventing any interruption to the business.

- Fast implementation enables businesses to quickly attain flexible, smart upgrades at a lower investment cost than fixed automation.

- The C200M’s door frame adopts a modular design and its height can be customized according to the needs of each customer.

- Modular components also make installation and deployment more convenient and can be assembled on-site without lifting, thereby easing transportation and loading.

- C200M can be connected to a variety of automation equipment such as conveyor lines and other robots, which is convenient for integration and customized project deployment.

With constantly rising labor costs and escalating labor shortage issues, “Goods-to-Person” picking has overthrown the traditional “Person-to-Goods” model. Robots are safe, reliable, highly efficient (picking efficiency multiplied by 3), and have a quick ROI period (1-3 years). Based on Geek+ patented algorithms, C200M leads the industry in various areas like thermal analysis, route planning, and hit rate.