Editor’s Note: The following article is brought to you by Cloudleaf in partnership with the Supply Chain Network.

Global competitive markets are eclipsing local economies, time-zones and jurisdictions by forcing supply chain ecosystems to evolve. Enterprises are following suit and digitally transforming their businesses in order to broaden their reach on the world-stage. These globally integrated supply chains have the potential to facilitate cooperative stakeholder relationships and help enterprises quickly source materials from a wider network of suppliers at lower cost. Tomorrow’s supply chains represent catalysts of innovation that enable unique technology solutions to deal with the complexities of running highly autonomous, perpetual operations in discrete and process manufacturing.

However, coming down from the 30k foot view, the realities on the ground can be quite different. In the global economy, many enterprises continue to struggle with maintaining transactional security, product quality, and keeping counterfeit materials out of their supply chains. And on the front lines, operation managers are under more pressure than ever before to keep products flowing, stay productive, and cut costs; all while working within an ever expanding ecosystem of supplier inputs and distributor outputs. So any interruption in the flow of goods, and the materials that go into them, is enough to keep operation managers up at night. Inaccurate inventory levels, down equipment or misplaced assets have the potential to set off a cascade of failures that ripple through the supply chain, increasing costs and introducing valuable opportunities for the competition.

Blockchain Overview

Occasionally technologies emerge with just the right mix of vision and potential to produce a “perfect storm.” These represent watershed moments that have the ability to shake-up markets, solve real-world challenges and create value that extends beyond the bottom line. Blockchain is such a technology, carrying the potential to actualize synergies between stakeholders, generate sustainable business value, and enable enterprises to easily expand operations into emerging markets.

Blockchain is more than a technology but a movement that is transforming how transactions are processed. It is also rapidly gaining momentum outside technology circles and fueling innovation in next-gen supply chain systems. At the basic level, blockchain is a digital technology for securely recording, storing, and verifying transactions. It provides a distributed database, or ledger, with records of data and transactions that does not require a centralized point of control. The database is easily accessible for users to review and audit, without providing the ability to alter or delete previously recorded transactions. Altogether, blockchain technology enables a permanent history for data or transactions, resulting in greater transparency and resiliency of the digital records.

If we take a deeper look into blockchain technology, we find several defining characteristics:

- Robust Data: Imagine a “spreadsheet” that is copied to thousands of computers across a network, updated on a regular basis. This is a core concept of blockchain technology: A distributed database replicated across the blockchain network that eliminates a single point of failure and ensures the integrity of each record.

- Security: Each new record, added to the blockchain database, is a smart contract or transaction that uses part of the previous record in its metadata, thus creating the chain of blocks that denotes the term ‘blockchain.’ Altering one record or contract in the database would not be feasible, as it would require an override of the entire blockchain network. And because the database is not stored in a single location, there is no centralized version for bad actors to manipulate or corrupt.

- Transparency: Now, think of the distributed database as a Google Doc rather than a spreadsheet. Where the traditional workflow of sharing spreadsheets only allows one party to make changes, Google Docs enables concurrent processing of the same document by all parties. Blockchain technology allows for permissible and real-time public access, so all authorized parties can view the historical ledger of records and sanction updates to the database.

So how does blockchain technology impact supply chains and why is it critical for operation managers to quickly get up to speed with this technology?

In the news, cryptocurrencies are dominating press headlines, but behind the scenes, industry observers are quietly analyzing and validating potential applications for blockchain technology across a variety of industry use cases. For example, according to IDC one-third of manufacturers will be tracking the status, location, and condition of goods using blockchain technology within the next three years, to better understand the movement of goods across supply chains.

Transitioning from Manual Workflows

In the past, manual transaction methods were well suited for simple operational models that sourced materials from a handful of local suppliers and serviced a single distribution channel. However, many supply chains now span multiple warehouses, stores, and facilities, in various countries, around the world, yet most transactions are still reliant on inefficient, error-prone paper-based records. The sheer volume of touch points in a typical global supply chain is revealing the fundamental weakness of the manual transaction processing approach. Paper-based record keeping is simply not designed to scale growth or handle the increased volume of transactions, complexity or security required by a globally integrated supply chain. Even more problematic are the large data repositories this approach creates that reveal very little of what is happening on the front lines. The emergence of the Industrial Internet of Things (IIoT) and other cyber-physical systems rising out of Industry 4.0 best-practices are enabling enterprises to implement pervasive wire mesh networks (WMN) made up of thousands of smart-assets and workflows to fully leverage the operational technology (OT) domain.

Syncing Up The Chain

As supply chains become more globally integrated and their data flows more distributed, these congruent technologies emerging are capable of reconciling the complexities and security concerns of processing millions of decentralized transactions. Blockchain recordkeeping platforms specifically address these issues. Global trade management involves several layers of stakeholders, including upstream suppliers and producers, export and import authorities, shipping and logistics, and distribution and retail channels. So how can blockchain implementations build trust and transparency within the digitized document workflow and improve the efficiency of the global supply chain?

Each time products, goods or raw materials change hands in the supply chain, documentation needs to be created, approved and executed. Whether that looks like raw materials being processed in production facilities, regulatory agencies approving the import and export of goods, documentation describing product origin and quality, shippers transporting containers of product, or retailers selling to end consumers, transactional data is often locked away in organizational silos creating lack of reliability at certain touch points along the chain. Digitizing the paper trail brings a new level of transparency that mitigates transactional errors, counterfeit goods, and excessive dwell times which reduces potential of product recalls, waste and helps lower TCO. Stakeholders can verify which documents are associated with which production lot, who is in possession at any given time, and what next steps are in the supply chain journey.

An Extension of IIoT

Enterprises are moving to digitize their supply chain processes in order to achieve new levels of visibility and proactively manage costly interruptions. Blockchain offers a promising collection of distributed technologies, databases and connectivity solutions that, combined with IIoT solutions, has the potential to transform an enterprise’s reactive legacy manufacturing processes into a proactive global supply chain of cooperative partner relationships. It’s an exciting time for operation managers looking to streamline the ebb and flow of materials passing through their facilities. And the sustainable value blockchain offers is compelling. Delays from equipment failure, unplanned maintenance, unreliable inventory levels, security breaches, compromised product quality, questionable material sourcing and inefficient labor utilization will soon be a thing of the past. A component of the larger IoT movement, blockchain is transforming supply chains by providing transparency across internal and third party facilities that enables managers to focus on core-competencies, optimizing resource usage, increasing productivity, and maximizing profit.

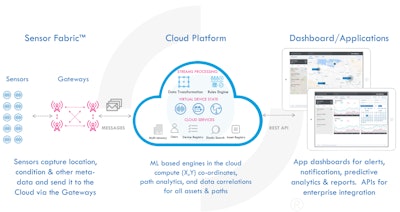

Cloudleaf embraces this blockchain movement with interoperable mobile technologies to provide out-of-the-box value. Cloudleaf’s Sensor Fabric™ focuses on solving transactional workflow bottlenecks through a mesh of sensors and gateways that sync OT data with user-friendly cloud systems. Cloudleaf provides blockchain-agnostic APIs written at the cloud level to allow participation with any blockchain ledger and automatically update transactional records, further alleviating manual transactional processing.