Does planner workload affect productivity? Can technology help companies achieve a step-change in productivity? The answer to both of these questions is yes and here are some data-driven facts to consider in your pursuit of productivity.

Slow growth in recent years is making productivity a key priority for leadership. Strategies to raise productivity typically include investments in technology advances to increase output or layoffs to reduce hours worked. Many companies are taking the route of cutting headcount to reduce sales, general and administration (SG&A) expenses, but at what cost to the organization?

At the same time, there is a lot of industry talk about prescriptive analytics that use real-time data, algorithms and automation to enable a surge in productivity and performance. Analysts are calling this the digital supply chain; and the World Economic Forum refers to it as the Fourth Industrial Revolution. Sounds great, but is this hype or reality?

To answer these questions, this year’s E2open Forecasting Benchmark Study looked at the impact of planner workload on productivity, and whether technology using real-time data, algorithms and automation can substantially raise it. For those not familiar with the annual Forecasting Benchmark Study, it analyzes the demand planning performance of 17 multinational consumer products companies and is the largest study of its kind, encompassing over $250 billion in annual sales, 9 billion cases and 1.6 million SKUs.

As a way to quantify the impact on productivity, workload (in terms of the number of base codes managed by each full-time planner) was compared to forecast value-added (a standard metric to measure the value provided by planning systems, processes and people). The dataset finds a correlation between workload and productivity; as workload increases, the value-added achieved by investments in traditional demand planning systems and processes declines. This reinforces the value of providing planners sufficient time to manage items in their portfolio.

Higher workload is also linked to increased levels of extreme forecast error (when forecasts fall short or exceed sales by more than two times). Extreme error is the most disruptive and costly error to the supply chain, eroding margins with additional logistics and holding costs, as well as increasing the rate of product cuts and lost sales. So while shrinking headcount provides an immediate lift to financials, companies that cut planners should expect to see a reduction in value-added and more extreme error, both which multiply costs across the supply chain. In short, you can’t cut your way to sustainable growth.

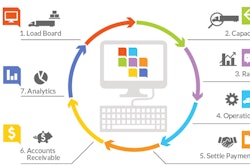

Data from the study shows that, for any given workload, demand-sensing technology provides a step change in raising forecast value-added and reducing extreme error. To the earlier question, the use of real-time data, algorithms and automation in demand planning pays off. It is not that automated algorithms are smarter than people, but much faster. This makes them uniquely positioned to analyze staggering amounts of data, leverage complex patterns to align sales projections with current market realities and do it all in time to publish daily forecasts for every SKU every day. Offloading mundane, complex, number-crunching tasks to algorithms augments planners and allows them to focus their valuable time on strategic activities that require human insight. The result is an immediate boost in productivity and better return on investment in demand planning systems, processes and human resources.