Predicting the future. It sounds a little out there, but when organizations design the structure and policies for future supply chains, that is essentially what they are trying to do. They are asking questions like: How will the supply chain perform two months from now? How would a change in strategy impact service levels and costs? When will we stock-out? Will we have late shipments?

To get these answers, you could rely on good old-fashioned extra-sensory perception, but a more realistic and reliable form of ESP is enterprise simulation planning. Enterprise simulation planning allows businesses to see how their current supply chain will perform under future demand levels, potential alternate supply chain structures, changes in policies and risk reduction strategies. Armed with these insights, businesses can create a continuous process for supply chain improvement and innovation.

How Does Enterprise Simulation Work?

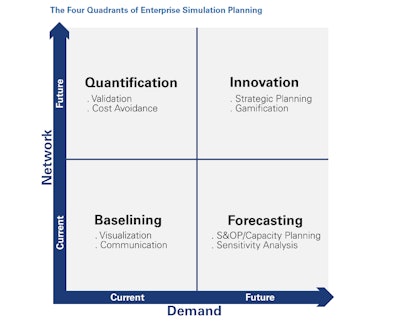

There are four distinct use cases for enterprise simulation planning that offer four unique benefits to an organization. It’s simplest to visualize them in quadrants.

Baselining: Current Network/Current Demand

Modeling and simulating the current network using the current demand (i.e. the most recent historical supply chain transactions) is an essential starting point for all other forms of analysis and is typically referred to as the baseline.

The baseline is like the control in a scientific experiment. Once the baseline simulation is validated to show that the behavior, flows and costs match those that happened in the real world, the analyst achieves confidence in the model’s behavior, and can use the model to compare against new simulations that explore changes to structure, policy or demand. Seeing the as-is supply chain in maps and graphs is a way to identify inefficiencies and other problems, and create a consensus among all stakeholders, minimizing people’s ability to challenge the results of future what-if experiments.

Quantification: Future Network/Current Demand

Simulating the future network using current demand can help an analyst to quantify a theoretical change to the supply chain structure or policies before implementing such a change in the real world.

Simulating different what-if configurations of the supply chain network can help quantify the cost and service level impact for questions such as: What if we change to twice-weekly replenishment? What if we source from Mexico instead of China? What if we change our inventory targets? Running detailed simulations of these decisions can help companies avoid the costs associated with bad decisions by predicting these costs ahead of time and comparing the results vs. other, more appropriate network decisions.

Forecasting: Current Design/Future Demand

Simulating the current design using future (forecasted) demand can help an analyst predict operational challenges such as capacity limitations, product stock-outs, delayed deliveries or supply shortages.

Companies spend an enormous amount of time and effort to forecast future demand. These forecasts have varying levels of accuracy, but can be extremely useful when coupled with enterprise simulation planning models. Running simulation scenarios with different potential forecasts can identify the limits a supply chain can handle before running into operational difficulties. For this reason, leading companies often incorporate these simulation models into their corporate sales and operations planning (S&OP) or capacity planning processes.

Innovation: Future Demand/Future Structure

Modeling new supply chain network strategies with new projected demand is required when trying to innovate and proactively move the business forward.

Transformational decisions often do not have a historical reference or transactional history, nor do they always have an existing supply chain network from which to create a model. However, simulating future networks with projected future demand is incredibly useful in testing transformational ideas such as merger and acquisition (M&A) activity and validating theories prior to making these often risky moves. It also enables companies to try gamification strategies by turning analysts loose to create and test new supply chain designs, and encourages innovation and entrepreneurship within the team.

Case Example: The Value of Simulation Planning

Global tobacco powerhouse British American Tobacco noted that several inefficient processes were negatively impacting its supply chain and put enterprise simulation planning in action as a way to test potential supply chain changes before implementing them. After creating a baseline model of the as-is supply chain, the company was able to have a theoretical planning strategy session in which it could test different scenarios in the comfort of a risk-free simulation environment.

By simulating each transaction and the resulting decision as it would happen in the actual supply chain, British American Tobacco was able to determine that new product segmentation and manufacturing strategies could result in a 40 percent improvement in stock levels, as well as result in dramatic improvements in work center change-overs and adherence to production plans. The company since implemented this strategy in its Mexican and Asian production locations, and found that the potential savings shown in the simulation could actually be achieved.

Simulation has become an integral component of supply chain strategy for a growing number of global businesses, operating hand in hand with supply chain optimization. Because simulation truly factors time and variability into each individual transaction, decision and movement throughout the supply chain at stock-keeping unit (SKU)-level detail, this ESP method is extremely useful as a way of testing potential network changes before enacting them, reducing risk of strategy changes, and supporting continuous supply chain improvement and innovation.