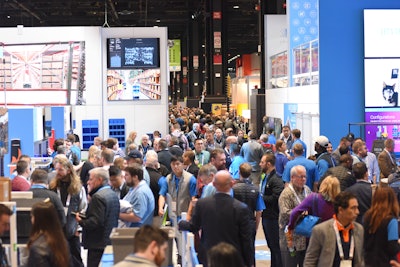

ProMat 2025, which took place March 17-20 at McCormick Place in Chicago, featured many vendors, manufacturers, system integrators and other industry experts in the material handling and supply chain space. The activity and energy remained strong throughout the event and the ideas were flowing as companies look to improve their operations.

Jackie Harbison, director of product innovation for Fives Intralogistics Group, says, “The foundation of any successful system is knowing the customer and being able to work collaboratively is key. With product innovation, the most important thing is understanding the customer’s problems,” during the panel discussion “Maximizing Automation ROI: Overcoming Operational Challenges.”

Maximizing ROI was certainly a common theme during the many visits, but it also was about making things simpler and more efficient for workers.

GMR Safety’s POWER CHOCK Auto is an extension of the existing system and is designed with optical sensors that can detect vehicle wheels up to 21.5 feet from the loading dock wall.

Jay Jetté, founder and CEO of GMR Safety, said during a press conference that a person dies every day at the loading dock; these automated solutions are designed to keep workers away from potential harm.

Gorbel’s Destuff-it 2.0 is an expansion of its ergonomic conveyor offerings and is designed to improve warehouse automation. Daniel Speiser, marketing project planner, says it has a cascading belt conveyor and has a crab-walk design that makes it easier to move from spot to spot for loading or unloading. The platform itself is also configurable from 8-30 inches, creating greater flexibility for the operator and helping to reduce injuries.

HeroWear’s Apex 2 is a back-assist exosuit with a particular emphasis on the lower back and is mechanical in nature. It doesn’t need to be plugged or powered. It’s also designed to be modular for the wearer.

Jennifer Jones, director of client services, HeroWear, says, “We’ve made sure it can fit as many individuals as possible because the first thing we’re often asked is: ‘Is it going to fit me?’” She adds that she's seen people less than 5 feet tall and more than 7 feet tall be able to wear the Apex 2. It also reduces up to 40% in fatigue, and case studies show how the ExoSuit is reducing workplace injuries, which not only reduces downtime and worker injury, but also helps with worker retention, which remains a major challenge for companies.

An Optical State Capture were among the highlights at Kardex’s booth. It is designed to capture and analyze data to deliver performance tracking and improve process optimization. The intuitive picking assistant (IPA) uses digital tools and augmented reality (AR) to respond to workers’ movements and project relevant picking information directly onto the surface of the access opening. It also has the ability to determine why an unwanted inventory adjustment occurred. It does this by capturing operator interactions, changes in the cube, and inventory images. AI technology can then review the entire process and interaction so users can learn.

Tj Fanning, VP, sales, says, “It’s designed to enable your full remote cycle count and enable you to pick more accurately and maintain that accuracy throughout."

During Jungheinrich’s press conference, Devin TePastte, senior manager, aftermarket sales and support at Mitsubishi Logisnext Americas Inc., talked about its online fleet management system, which allows dealers to track and monitor worldwide and enables users to ask service work dealers about any information inputted.

Michael Bloom, director of connected solutions, says its customers come with unique problems and the solutions are always different. “There are limitless possibilities in how we can solve problems.”

Powerfleet’s Unity platform is designed to integrate with Internet of Things (IoT) devices and provide data-driven insights to improve forklift telemetry information and, in turn, worker safety.

Marc Osgoodby, VP, sales for Powerfleet, says they’re focused on layering safety solutions and making them customizable to fit any application. He also mentioned the cameras used to process and capture the scene around the forklift are AI-driven and linked to the platform to create better insights for companies so they can deploy preventive measures.

UniCarriers’ forklifts are designed to help businesses enhance operational efficiency and drive productivity in outdoor settings. Chris Stanley, material handling sales leader for Mitsubishi Logisnext Americas, says the highlighted forklifts are electric and designed to work in harsh outdoor environments. They boast an 80-Volt battery system with 8 hours of runtime and are designed to produce the same power as an internal combustion engine (ICE).

There’s a lot of potential for automation out there, but as the panel discussion with the Fives Intralogistics team proved, it’s part of a much larger discussion.

Monte Herford, director of project management for Fives Intralogistics, says “The best projects, in my experience, is when engineering gets site operations into the discussion. They’re going to have the best ideas. Companies need to engage the broader audience and have that conversation. When you have it and they feel included, they’ll buy in because they feel they have ownership.”

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)