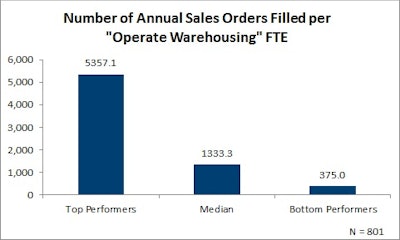

The most resource-intensive logistics process is warehouse operations. This process is the most complex and usually presents the greatest opportunity for improvement. The number of annual sales orders filled per “operate warehousing” full-time equivalent employee (FTE) is a good proxy for warehouse operation efficiency. The more sales orders a warehousing professional can manage, the fewer people (and headcount dollars) are needed to support the process.

As shown above, American Productivity and Quality Center’s (APQC’s) Open Standards Benchmarking in logistics shows that warehouse operations FTEs in top-performing organizations can fill nearly 5,000 more sales orders per year than their counterparts in bottom-performing organizations. The difference between the two groups is considerable.

Standardizing processes in warehouse operations increases efficiency by making it easier to fill sales orders with the appropriate number of FTEs. Implementing quality assurance measures is also important when looking at the number of sales orders filled to ensure that faster throughput does not result in increased errors.

Many leading organizations are also turning to sales order processing systems that have effective interfaces with many other application systems (i.e. financial accounting systems or accounts receivable systems) to help fill sales orders more efficiently.

Organizations are also setting up status codes for each step in the sales order process using order activity rules (e.g., codes that track the status of an order within the process from the beginning until completion of a sales order).