The world is moving at an unbelievable pace, and nowhere is that more apparent than in technology. As available technologies expand and become more advanced, the line between the physical and virtual worlds gets more narrow. The physical side of technological advancements includes computers, mobile devices and sensors, while the virtual side is the software running on those physical devices.

Within the supply chain, various stakeholders run a wide variety of software solutions. These technologies manage operations, keep track of assets, plan shipments, complete transactions, identify new business opportunities, communicate with employees, monitor compliance and handle maintenance needs. Each of these solutions, which may be provided by different technology providers, represents a “node” that collects data.

While back-office shipper, broker, third-party logistics (3PL) and carrier staff have long used computers to manage operations within a transportation management system (TMS) or warehouse management system (WMS), the U.S. electronic logging device (ELD) mandate and upcoming Canadian ELD mandate have rapidly accelerated the use of physical technology in each truck that’s on the road in the form of in-cab e-logging devices. The newfound ubiquity of technology within the trucking sector has unlocked huge potential for the industry to create a network of nodes that communicate with each other.

By connecting all of those nodes together as a single network rather than individual fragments, new opportunities for collaboration can be found within the supply chain – opportunities that simultaneously improve uptime, create efficiencies and reduce costs.

Bringing events together

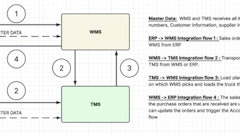

There are many pieces of a shipment’s journey that must be managed correctly in order for it to get from shipments from origin to destination. Many solutions may be used along the way, including an enterprise resource planning (ERP) system, a procurement system, a TMS, WMS and more. A connected supply chain would bring the data from each of these solutions together into a single network platform, regardless of which provider developed each specific tech solution.

Additionally, each role within the supply chain, whether it’s a shipper, carrier, broker or 3PL, has a different set of goals and needs. These are similar enough that increased visibility into each other’s data would give all stakeholders the ability to collaborate more closely and create efficiencies.

In the past, tech solutions in the supply chain were built to stand alone or only integrate with the other solutions within that company’s portfolio. This led to a very painful – and expensive – rip-and-replace mindset around hardware and software solutions that has ultimately become unbearable for the industry.

The good news is that pain helped create a new way of doing business, and those painful days are gone. What transportation and logistics companies need now is the ability to integrate all of the discrete solutions within their own operations, as well as to third parties, in order to keep shipments moving quickly and effectively.

Allowing users to access a more modular network of apps is what will eventually create a best-in-breed system that enables more transparent data visibility and collaboration between parties. It will bring down the cost of doing business while increasing efficiencies and enabling even more advanced analytics and insights.

The future is now

The supply chain industry is only now beginning to scratch the surface of what is possible when advanced technologies are leveraged in tandem. As the world continues moving and changing, two of the most exciting new areas in technology are cryptocurrency and blockchain. These two technologies are very buzzworthy and often misunderstood, but the potential that both hold is amazing.

Blockchain is a new way to securely validate transactions and cryptocurrency is an alternate mode of payment for services. Both of these new forms of technology often go hand-in-hand as modular solutions, just like the connected supply chain. In fact, the network of connected nodes could be driven by blockchain, encrypting and validating every transaction that occurs throughout a shipment’s journey, and payments could be made using cryptocurrency.

The retail and warehousing sectors are already being transformed, but will continue to see massive changes in the near term as companies become more “intelligent” about what they’re stocking and how they stock it. Every day we move closer to a future where retail stores are more like showrooms, with customers ordering products in store for next-day – or even same day – home delivery. This future is enabled by increasingly advanced and connected technology.

While there is still work to be done over the coming years to bring these ideas into everyday use, these are no longer crazy, futuristic concepts. Instead, these futuristic technologies are currently being built, which means that the rest of the supply chain will need to catch up in order to be ready to take full advantage of the value they provide.

The supply chain fuels the world, so how are we fueling the supply chain? Preparing for a more collaborative, modular environment is the first step to enabling the supply chain of the future.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)