Fictiv unveiled industry-first features that deliver unprecedented visibility, traceability, speed, and quality, benefits for customers leveraging its Digital Manufacturing Ecosystem (DME) to order high-tolerance, custom mechanical parts for both prototyping and production needs. As part of its radical transparency initiative, these new features bring into focus the otherwise opaque nature of traditional onshore and overseas manufacturing and introduce significant risk mitigation and cost-savings opportunities.

“Historically, companies were working in the dark, relying on phone calls late at night, file transfers, emails and time-consuming site inspections, when it came to overseas manufacturing – a risky, expensive process that often resulted in delays and quality issues,” said Fictiv CEO Dave Evans. “Fictiv’s groundbreaking new radical transparency initiative is better because our quality engineers and customers can inspect a part all along the way. These features introduce a disruptive set of visibility controls and prompts that peel back the covers and make it possible for engineers and supply chain managers to clearly see, communicate, and track progress with manufacturing work and come away with complete confidence in quality outcomes, delivery times, and costs.”

Key Transparency Features

Available today, Fictiv’s radical transparency initiative includes these key features:

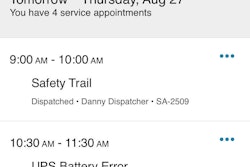

- On-Demand Production Status: detailed current production status of all the parts within every order, immediately and online;

- Virtual Inspection Photos: inspection photos from the manufacturing partner facilities, before the parts are delivered;

- Centralized Access to Quality Documentation: material certifications, certificates of conformance, and inspection documentation all available in one place;

- Order Configuration Details: centralized access to 2D and 3D design files, thread specifications, material and process configurations, and invoices for all Fictiv orders;

- Historical DFM: digitally call up previous manufacturability feedback for all ordered parts to inform future design cycles;

- Reorders: streamlined quoting process to reorder parts and lock in previous pricing;

- Shipment Tracking: aggregate tracking links from third-party providers to keep all shipments in one secure place.

“Fictiv eliminates the need to spend time, money, and resources on sending teams of people overseas to inspect partners and facilities – a challenge even more pressing during this global pandemic,” continued Evans. “Our new transparency features transform the process of physical parts inspection into a seamless, digital one that saves time and costs while improving quality and time to market.”

Impact of Transparency

Gregg Miner is a product development and prototyping specialist who has spent his career helping bring products to market for companies like Oculus, Facebook, Apple, and Bell Helmets. In previewing the new radical transparency initiative from Fictiv, he highlighted its unique standing in the industry, compelling cost savings, and innovative capabilities.

“Quality control for overseas manufacturing is an expansive, herculean effort, requiring multiple week-long trips every year pre-pandemic for an entire team, totaling hundreds of thousands of dollars in hard expenditures and lost opportunity costs,” explained Miner. “Now, there isn’t even an option for travel, forcing companies to accept whatever product shows up at their door. Fictiv is breaking new ground with its initiative - no one has ever attempted this level of robust transparency at this scale before. I am excited to see this become the gold standard industry-wide as it will completely transform the way we conduct business.”