Faced with a dynamic and changing business environment, many organizations are finding traditional planning, enterprise resource planning (ERP), procurement and transportation system solutions extremely aggravating to work with. This is because so many supply chain solutions are incapable of properly supporting decision-making analytics, business objectives, and the autonomous supply chain due to the convoluted process design/flow within the business system configuration.

In most cases, ERP systems require some level of customization to adjust for lead times in planning, order management, and transportation, which in turn impact demand management, inventory, and capacity across an organization’s own operations as well as its customers and suppliers.

A new model for better business outcomes

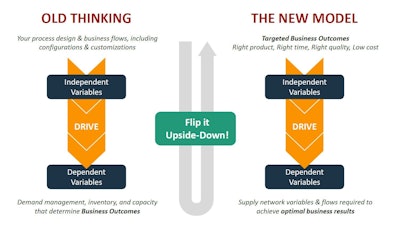

Under the old model, these hardened process designs, business flows, and customizations determined (and limited) how you operated and determined your business outcomes. In the new model, let’s define the targeted business outcomes that we want – the right product with the right quality with the right service levels at the lowest cost - and then determine the supply network business practices necessary to achieve optimal results.

So, we’re turning this upside down and instead of the data as the dependent variable, let’s make it the independent variable. This is what machine learning (ML) is all about. Here, the data defines the relationships and thus the equations. It is a little scary in the sense that not many people really understand the nature of the relationships that are built within ML, but the outcomes speak for themselves.

Anyone who has any type of artificial intelligence (AI) or ML initiative in place has already turned their problem-solving approach upside down. Prior to ML, organizations basically had to fine-tune various types of mathematical equations to give them a near optimal result. The independent variables were the math equations and the fine tuning was very situational and problem-type specific.

By turning the typical problem-solving approach upside down, business and trading networks in all industries can generate significant results. Deploying a full demand/supply trading network in real time across all trading partners in an industry network - from planning to ordering to procurement to transportation to delivery –provides the foundation for companies to be data-driven rather than driven by static, old data available through legacy ERP approaches. So, what’s required to make this possible? It boils down to two key components:

1. Apply autonomous decision-making to the greatest extent possible

AI/ML and the application of these techniques to prescriptive problem solving provides only half the capability required to turn the supply network upside down with decisions driven by desired outcomes rather than stale process data. The other half of the capability is provided by a set of robust network-based multi-party software services across demand, supply, logistics and fulfillment, which can be tuned to operate autonomously, based on creating the desired process outcomes.

By moving to a real-time demand and supply network across all trading partners, businesses are able to identify and address more problems and issues than they ever could in the past. In fact, given the scale of today’s supply chains and the tens, thousands or millions of monthly transactions, companies face volumes that exceed human capacity. As a result, many are seeking to take full advantage of automation technology.

However, the ability to generate improved business results quickly and avoid increased lead times, inventory and excess capacity, its critical to define decision guardrails and automate decision-making to resolve problems that occur as a normal course of business. In other words, we need to automate routine, repetitive decision-making to the greatest extent possible. Fortunately, great strides are being made in this area, which allows organizations to liberate staff members to focus on higher level jobs and carry out this next performance optimization objective.

2. Apply the power of prescriptive analytics to optimize performance

Even more interesting is what is happening with AI/ML-based prescriptive analytics. If we truly have a solution architecture that is focused on the outcome we want to achieve, then we need to be able to adjust every other variable in the network (within reason) to derive the desired result. Rather than adjusting variables like lead time, inventory and capacity to the old levels, which led to poor performance in the past, the AI/ML overlay now drives the entire network to achieve optimal operating performance while also achieving the targeted outcomes.

For example, a multi-echelon supply network problem can be solved in many different ways, including adding shifts, expediting, allocations, postponement and more. In fact, certain problems can have 4-5 different solutions involving many different parts of the supply network, each having a different business effect on the network outcome. An AI engine can rank these choices based on various business strategies. For example, market share vs. revenue vs. margin generation vs. customer service vs. resiliency, etc. However, there are many other variables that planners, schedulers, distributors, shippers, operators and manufacturers may also want to consider when choosing a problem resolution that the solution architecture and advanced workbench capabilities can address.

The types of problems that are elevated to the advanced workbench are those “outside the guardrails” of the normal course of business. These problem-solving workbenches are set for autonomous problem-solving and are highly material to business outcomes and optimal performance. As a result, these workbenches provide a unique opportunity for companies to differentiate themselves when it comes to exceeding customer expectations, increasing service levels and gaining market share, while at the same time driving cost improvements and margin growth.

Applying prescriptive workbenches to achieve positive outcomes

Without a real-time view of the end-to-end business network, it’s virtually impossible to offer this level of decision-making options because they don’t have access to the same data across the network. This means the range of choices will be incomplete or inaccurate, or both, resulting in sub-optimization and poorer performance relative to competitors.

Then, once a decision is reached, the business still needs the ability to execute decisions operationally and in real time if necessary. After all, knowing the best choice without the ability to execute is really no choice at all.

Leveraging an AI-powered real-time demand and supply digital network, organizations can set a course based on the business outcomes they want to achieve. Thanks to a series of prescriptive workbenches across demand, supply, logistics and fulfillment, they are also optimizing their decision-making based on targeted outcomes. Outcome-driven solution designs are becoming the new normal for all operating and trading partners, and rightfully so, as organizations look to up-end antiquated approaches and turn their businesses - as well as their technology – upside down.