With the advent of the Internet of Things (IoT), there is tremendous potential to change the very structure of the supply chain from a linear, step-by-step process into a seamless, data insight-driven stream. Supply chains around the globe are currently being challenged by volatile demand patterns, cutthroat competition and increasing consumer expectations for fast delivery speeds. In recent years, conventional levers were implemented to improve supply chains, along with the gaps these levers still cannot fill.

Grinding Ahead with Traditional Levers

Companies recently explored a gamut of levers in their quest to optimize supply chains. Most of these levers are structured around one of three categories: people and process, information technology (IT) enablement and industrial automation.

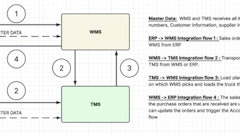

People and process levers improve efficiency by process engineering, policy change and organization redesign. IT enablement levers can improve supply chains by facilitating communication between various stakeholders and entities in the supply chain. Many of these levers work at a process transaction level, and evolved over a period of time from electronic data interchange (EDI) to advanced enterprise resource planning (ERP) systems and supporting applications. They give customers access to tremendous amounts of information anywhere and anytime.

Industrial automation levers automate supply chain elements, such as warehouses, shop floors and logistics. Automation, as we learned since the industrial revolution, greatly reduces manual efforts and human errors.

Pull all three levers and there’s no doubt that the customer experience is improved. But while traditional levers tend to make a supply chain gain some speed and efficiency, there are still significant gaps and few opportunities to innovate. In short, there’s still no wow experience.

This can happen because conventional levers are investment-intensive and, therefore, costly and difficult to modify, requiring a long period of time to reach a break-even point. Since they often consume a huge part of a budget, they leave little scope for supply chain managers to engage other initiatives.

Generally, the supporting IT systems of traditional levers operate at a process transaction level. An analysis can provide a holistic view, but completely miss the root cause of inefficiency at the sub-transactional level.

How IoT Fills the Gaps, Creating a Stream

Given accelerating pressures, further investment into traditional levers is risky. There’s an obvious need for a lever that requires incremental investment; is flexible for deployment and modification; operates at a sub-transactional, granular level; and prioritizes the customer rather than the process.

IoT-enabled levers can do exactly that. IoT would not eliminate conventional levers, but fill in the gaps, creating a seamless supply stream by enabling more innovation, communication and an enormously improved customer experience. It is an ideal candidate for transforming supply chains in key areas: warehouse, inventory, logistics and new product development. From product development to delivery, IoT fills in the gaps left by conventional supply chain levers to create a seamless, predictable and enormously more efficient supply stream.

IoTization of the Warehouse

Integration between intra- and inter-logistics components, which was not possible at an ERP level, can now be enabled by leveraging IoT. This reduces wait time and streamlines coordination between logistics providers and warehouse managers. Finally, supply chain managers can better coordinate and manage inventories because IoT enables tighter integration between warehouse inventories upstream and downstream.

IoTization of Inventory Management

A key challenge for supply chain managers is inventory traceability. IoT, with its sensory capabilities, can provide a multi-level view that includes in-transit and at-rest inventory across all echelons. Supply chain managers have a visual of their entire inventory at any given point in time.

A typical pain point in inventory management is the glaring discrepancy between actual physical inventory and what’s shown in records. IoT can integrate data from logistics to provide an accurate and comprehensive view of replenishment and withdrawals. Warehouse managers can rest easy, even after inventory audits.

IoTization of Logistics

While global positioning system (GPS)-based tracking has been in use for a long time, the data from GPS systems is confined to limited space and usage. IoT platforms can marry this with other transactional data to provide logistics operators with a clear overview and the insights that support more tactical decisions.

Logistics companies potentially face huge losses in operations if they’re not able to align operations and weather conditions. Weather services now forecast weather changes at hyper-localized levels. As IoT goes about integrating this data with route schedules, companies can make more responsive, granular decisions at the route level. Logistics supervisors are better prepared when scheduling and routing shipments.

Transporting perishables can also be challenging. IoTizing the logistics management process can help avoid losses by continuously monitoring the health of the inventory and enabling precautionary steps.

And finally, as stringent regulations are placed on the hours of service (HoS) for drivers, it’s imperative that truck operators get real-time data on drivers. IoT can combine HoS with real-time route data to help logistics supervisors plan and schedule trips more efficiently.

IoTization of New Product Development

Supply chain managers often complain that supply chain inputs are barely considered in the creation of new products. A comprehensive view of a new product as it moves through a supply chain is key to developing superior products and delivering them efficiently to customers.

IoT can provide sensors and device capabilities, as well as the platform to view product movement through the supply chain. Product development teams can leverage this data and analysis to improve supply chain efficiency.

With IoTization, if a company wants to launch a beverage in a particular geography, it can understand exactly how that product will perform before launch. Using IoT, the beverage company can understand and optimize every supply chain and customer touchpoint of the product’s journey, and can bottle it, pack it, ship it and ensure that the customer experience is exactly what it intends. That’s how you make a wow experience.

From product development to delivery, IoT fills in the gaps left by conventional supply chain levers to create a seamless, predictable and enormously more efficient supply stream.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)