The dairy industry is an extremely competitive market with yogurt holding the title as one of the fastest growing segments. Yogurt consumption has almost doubled every seven years, making it a very attractive marketplace. Dannon competes with other fresh dairy providers to get products on shelves as quickly and efficiently as possible. In order to stay on top of the competition, Dannon is required to track hundreds of loads a day through its three manufacturing plants, six distribution centers and numerous trucks from third-party carriers.

In addition to the everyday complexity inherent in Dannon’s supply chain process, customers required better service through improved scheduling options and increased on-time deliveries. The former manual outbound and inbound appointment scheduling process required time-consuming phone calls; faxes; and emails between departments, shipping facilities and carriers. Additionally, the dock scheduler at each location was the only party with visibility to the entire transportation schedule, which created a bottleneck that limited the ability to communicate any delivery changes to the customers.

Solution implementation

To overcome such market challenges, Dannon utilized Holland, Mich.-based LeanLogistics’ On-Demand TMS to get ahead of the competition by addressing increased demands from customers and the complexity of the company’s fast-growing, changing marketplace.

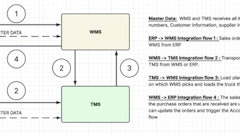

By integrating with Dannon’s SAP system, LeanLogistics’ On-Demand TMS Software as a Service (SaaS) transportation management system ensured end-to-end control over inventory, improved overall enterprise resource planning (ERP) and provided complete visibility. In addition, it supported the planning, execution, claims and appointment scheduling.

As a result, Dannon improved order accuracy, appointment scheduling, workforce performance, visibility and communication to more efficiently:

- Staff for special events and busy times well in advance with calendar-based LeanAppoint, which allowed users to schedule in open slots on-line versus calling Dannon to make appointments

- Monitor both arrival and departure appointments in real-time to communicate accurate delivery times

- Track priority deliveries to customer or distribution center and provide details on any delays with availability of real-time data to all load planners and transportation staff

- Research areas with frequent issues, pinpoint causes and address problems through reporting of service failures

- Review accessorial charges and automatic calculation of fuel surcharges for total shipment cost at any time upon load acceptance with visibility to all carrier dialogues

Added benefits continue

“We work in a fast-growing marketplace that has unique demands on the supply chain due to the shelf life of the product and our distributed operation,” said a company representative from Dannon. “With On-Demand TMS we are able to manage transportation from shipment tender through delivery, making service a competitive advantage.”

Visibility and collaboration provided by On-Demand TMS also enabled Dannon to increase customer satisfaction while freeing up internal resources to focus on other corporate initiatives.

With the added benefits Dannon continues to receive from utilizing LeanLogistics technology, the company can also:

Save Time—Dannon frees up approximately one and one-half hours per resource per day with LeanAppoint to allow resources to handle more important tasks on a daily basis

Improve Customer Service & Customer Satisfaction—Complete visibility into the transportation process allows all customer service representatives the ability to see loads quickly and easily, which provides open communication of any issues or delivery changes leading to customer satisfaction improvements

Reduce Costs—Dannon and associated transportation parties see carriers’ schedules, which allows for better planning for delays and changes resulting in reduced detention costs in the first year of usage alone.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)