Over the past five years, businesses across the manufacturing industry have dealt with numerous supply chain disruptions that have impacted their ability to maintain customer service levels, optimize working capital and have led to significant reactionary COGS through expedited freight, purchase orders and overtime. The dynamics have forced many to rethink their pre-pandemic inventory and supply chain planning strategies. Additionally, the increasing number of supply chain events has created an environment where companies responded by increasing inventory levels as a buffer to hedge against the effects of supply chain disruptions but led to vulnerability to excess and obsolete inventory as demand patterns have also been changing with increased frequency.

Companies have turned to AI-enabled platforms to help navigate a business and economic environment marked by volatility, uncertainty, ambiguity, and complexity (VUCA). As we head into 2025, companies are likely to leverage AI technologies to help transition back towards their pre-pandemic operating levels and focus on building greater agility and flexibility into their supply chains. Here are three potential use cases for using AI to hedge against uncertainty in the coming year.

Enhanced Scenario Planning Capabilities

More organizations are using AI technology to inform their short-term, mid-term and long-term supply chain planning capabilities, however, many are still somewhat rudimentary in how they execute their day-to-day tasks. In order to quickly identify and respond proactively to potential supply chain disruptions in 2025, companies need to fully optimize their scenario planning capabilities and should consider integrating their spreadsheet data into their planning platform.

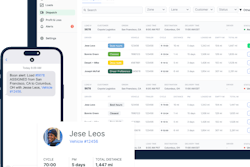

AI-enabled planning platforms are able to collect a company’s historical data and other relevant internal and external data points, then provide structured insights and map out actions that can inform real-time planning decisions. Advanced planning capabilities like control towers or digital twins enable planning teams to simulate potential outcomes, compare financial implications, etc., and present actionable recommendations to stakeholders and leadership when necessary.

As GenAI continues to be applied in planning practices, companies will be able to ask specific queries, and the platform will be able to gather data insights to help identify potential trends, challenges, and opportunities during the scenario planning process. For example, a use case that is emerging is companies leveraging AI to identify trends, such as over-forecasting by customers or underperformance in suppliers, allowing companies to address and correct the issue. While we can’t determine all of the factors that could influence potential supply chain disruptions in the coming year, companies that are able to utilize AI platforms that enable early disruption detection and enact data-driven planning strategies and proactive decision-making will be better positioned to strengthen their supply chain.

Touchless Planning

The future of planning is powered by advanced AI engines, reducing manual intervention, and boosting efficiency with Touchless Planning. But, without trust, planners spend too much time touching system outputs and end up making the wrong decisions. It’s critical to ensure the following components are in place to drive effective touchless planning including:

- High-fidelity Input Data: Planning systems require complete, rich, and accurate data as input, both historical and future oriented.

- Right Granularity: Data must offer precise information across various dimensions (e.g., time, market, product and product life cycle)

- Advanced AI Engine: AI algorithms must be able to handle complex data sets, identify patterns, deal with outliers, and learn over time to improve accuracy.

- High-accuracy Results: The output should be accurate, unbiased, reliable (avoids big outliers), and stable (low variations from one forecast to the next).

- Explainable Forecast: Explainability refers to a system’s ability to offer clear and understandable justifications for how it reached a particular decision.

- Feedback Mechanisms: Systems need to provide helpful feedback with detailed insights into how adjustments affect forecasting accuracy and forecast value add.

Organizations are increasingly looking to automate activities across demand and supply planning and enabling these capabilities provide critical, differentiated capabilities for manufacturing organizations.

Closing the Skills Gap

Another area where AI applications can be applied is supply chain talent and skills development. A critical challenge is addressing the supply chain planning skills gap and also aligning skilled talent with new technologies. Incoming talent may need to strengthen their on-the-job planning skill sets, and existing personnel may need to adapt to newer ways of working and acquire new skills related to AI and other emerging technologies. However, many companies still operate with outdated systems, so it is also necessary for companies to adopt advanced technologies to strengthen their supply chain management capabilities to tackle future challenges and disruptions that could impact their business.

Another area where AI-enabled platforms can help bridge the skills gap between incoming talent and employees who will be retiring in the near future is by enabling the digitization of tribal information so that newer employees can be “trained” based on the internal knowledge of more experienced employees. For example, if a newer planner experiences a disruption that is similar to a situation that more experienced planners had experienced previously, the platform has this data built into its recommended insights and a newer planner is able to use this information to guide their decision-making. Organizations that make investments to integrate digital tools and technologies to operate more efficiently and strengthen their supply chains against disruptions will build a greater competitive advantage going forward.

While we can’t predict what supply chain disruptions may crop up in the coming year, AI-enabled platforms and technologies allow companies to identify potential risks impacting their supply chain, bolster the skillset of their workforce, and find opportunities to collaborate and strengthen relationships with their suppliers, all of which can lead to greater supply chain resiliency.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)