Daimler, the world's largest truck manufacturer, will use three-dimensional (3D) printing to produce spare parts, the latest example of how digital technologies are radically reshaping automotive manufacturing and its supply chain.

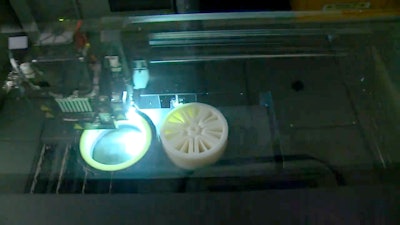

Rather than shipping vehicle parts across the globe, carmakers including BMW and Volkswagen are experimenting with so-called additive manufacturing. This relies on sending a digital blueprint of a component to a printer, which creates parts by using lasers to melt powders into plastic, glass, metals and even ceramics.

By printing new parts, automakers can save logistics and warehouse storage costs, and produce complex components at low volumes.

The technology is not ready to make high-volume vehicle components, so carmakers rely on conventional manufacturing methods for components like metal body panels, which are made using hydraulic metal stamping presses, costing up to 40 million euros ($44 million) each.

To read the full story, please click here.