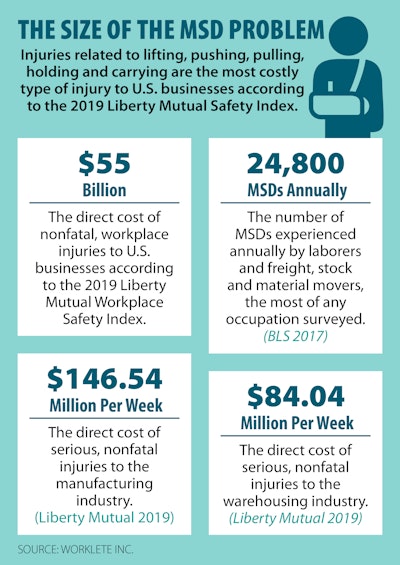

Workplace safety is an expensive problem. According to the 2019 Liberty Mutual Workplace Safety Index, U.S. companies incur nearly $55 billion in annual direct costs alone due to nonfatal, workplace injuries. While, $31 billion of this cost can be attributed to musculoskeletal disorders (MSDs), which are particularly common in transportation, warehousing and manufacturing industries, where repeated lifting, pushing, pulling and carrying on the job takes a toll on employees’ bodies over time. In these high-risk industries, annual direct costs from MSDs total $2.97 billion.

Not only are many employees in transportation, warehousing and manufacturing industries getting hurt on the job, but very few of them are engaged at work. A 2017 Gallup study found that just 30 percent of transportation workers and 25 percent of manufacturing workers were engaged at work, while the manufacturing industry had as many actively disengaged workers as it has engaged workers. The study also found that U.S. employees who are engaged at work are more likely to stay with their organization, reducing overall turnover and the associated costs. Companies in these industries are losing workers to injury and high turnover due to engagement. If companies in retention-challenged industries want to attract and retain quality talent, engaging employees at work is imperative.

So how can employers in these industries reduce MSDs in their workforce and build a strong safety culture that helps engage and retain employees? We’ve seen that investing in a sustained injury prevention program, not only reduces lost-time injuries and costs, but also has positive effects on retention and productivity, through culture. Here are three key strategies to consider when choosing a safety program that also strengthens culture:

1. Engage through Active, Participatory Learning

When it comes to retaining information, you can’t simply watch a video or listen to a lecture in a classroom. It’s been proven that participatory learning, whether it’s through group practice or teaching others, is the most effective way to retain information. This means that your safety program needs to integrate some form of group discussion, group practice, and teaching one another in order to instill safe habits that last. You need a mixed learning approach.

2. Leverage Online Microlearning

Microlearning - or learning in consistent, ‘bite-sized’ chunks - establishes everyday habits without taking an individual off the job for longer than a few minutes per week. According to the National Safety Council, the average cost of a workplace injury was $39,000 in 2017. Spending a few minutes consistently every week developing sustained, safe habits is worth it when you can save tens of thousands of dollars by preventing just one injury.

3. Provide Fresh and Innovative Content

The last piece of this puzzle is to provide fresh, innovative, and relevant content that not only informs your workforce, but engages them and keeps them coming back to learn more. Even the most informative safety program will fail to effectively impact your associates if the content is boring, difficult to complete or irrelevant to their job. By engaging your workforce with relevant content, they will maintain

Hub Group Trucking has seen the positive effects of implementing these strategies. The company has found that their safety program has helped build a culture of trust and appreciation, both between the company and its 4,400 drivers, and among the drivers themselves. By integrating a training program that emphasizes injury reduction and engagement, Hub Group was able to build a strong safety culture that not only resulted in a 63 percent reduction in lost time injuries and an 85 percent reduction in injury-related direct costs, but also increased productivity, on-time deliveries and driver retention over a 3-year period.

At the end of the day, everybody wants to enjoy their work and stay pain-free. When it comes to attracting and retaining quality talent, employee safety and engagement matters. For companies facing high turnover and injury rates, emphasizing injury prevention through a sustained safety program can strengthen the safety culture as a whole and inevitably have a significant impact on a company’s bottom line.