San Diego—April 17, 2012— Scientific enterprise R&D software and services company Accelrys Inc. issued an industry-wide call to close the productivity gap from innovation through commercialization that is slowing product development and time-to-market and hampering competitiveness for science-driven organizations.

To facilitate a new approach to effectively manage scientific innovation, the provider is introducing its Accelrys Enterprise Platform. It provides a scientifically aware, service-oriented architecture (SOA) that enables the integration and deployment of broad scientific solutions spanning data management and informatics, enterprise lab management, modeling and simulation, and workflow automation.

The productivity gap

For science-driven organizations—particularly those developing products based on modeling at the atomic or molecular level—there is a productivity gap that spans the entire innovation-to-commercialization cycle. This productivity gap exists because traditional information technology solutions have proved incapable of adequately managing the complexity of scientific data and processes and the volumes of unstructured data characteristic of scientific R&D. Scientific processes, for example, are difficult to automate and track, and therefore information is hard to access and reuse during the scientific and product innovation and commercialization cycles. Critical scientific insights and context from the discovery and development stages are never transferred to the commercialization operations of a business because downstream enterprise software cannot handle the unstructured data generated in the R&D cycle. Key parts of the innovation process are consequently lost, along with actionable insights that could bring novel products to market more quickly and cost effectively.

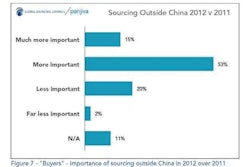

As a result of this productivity gap, innovation is slowing. Manual data collection creates costly bottlenecks requiring repetition and processes that can fail to comply with regulatory standards—potentially leading to rework or even product recalls, slowing time-to-market and threatening product quality. The productivity gap also hinders the ability of science-driven organizations to respond to industry trends such as outsourcing and globalization.

“The challenge for science-driven organizations is the large number of creative cycles required to develop and commercialize great innovations,” said Mike Burkett, Research Vice President at Gartner Inc. “Bottlenecks that slow down or reduce these cycles result in product of lesser quality or that’s late to market. Industries that have automated and integrated product and manufacturing process development have seen time-to-market improvements. Many science-driven industries remain in the early stages of adopting the same successful practices.”

Currently, only 25 percent of projects in industries ranging from pharmaceuticals to aerospace result in the commercialization of new products, according to IDC Manufacturing Insights. Of the 25 percent of products that make it to market, 66 percent fail to meet original design or consumer expectations.

“Effective, efficient, end-to-end innovation is critical to the competitiveness of science-driven organizations,” said Max Carnecchia, President and Chief Executive Officer, Accelrys. “Accelrys is committed to working closely with our customers and partners to close the innovation productivity gap. The Accelrys Enterprise Platform is a game-changer for organizations looking to deliver more competitive products, sooner and more cost-effectively to market.”

The Accelrys Enterprise Platform can manage structured and unstructured information encountered early in the innovation cycle, as well as highly structured, automated batch records required by lock-down production. Most importantly, the platform integrates with existing IT infrastructures, including downstream enterprise resource planning (ERP) and product lifecycle management (PLM) systems. The platform’s ability to integrate with existing infrastructure, as well as handle both structured and unstructured scientific data, allows science-driven businesses to gain efficiencies from their legacy systems, reduce complexity and improve productivity from innovation through commercialization.

“There is growing consensus that new product development is increasingly ineffective – especially for science-driven innovation,” said Joe Barkai, Research Vice President, Product Lifecycles Strategies, IDC Manufacturing Insights. “Scientific-driven research and development organizations are at a critical juncture—their homegrown systems no longer meet the demands of today’s fastest-to-market environment. They need to be managing the innovation cycle in a new way, and with the same rigor that they have managed their commercialization processes.”