Christmas creep recently entered the holiday shopping lexicon as retailers begin constructing storefronts with cheery décor and playing Jingle Bells before Thanksgiving is even a twinkle in the eye of many consumers. Add to that the flurry of online holiday shopping and the bottleneck those items can cause logistically when competing with coast-to-coast gift-giving. That means retailers are preparing earlier and earlier for the onslaught of consumers, and to compete, so must you. Are you ready?

According to Melanie Alavi, UPS Retail, “With the rise of online shopping, the holiday season is more compressed and retailers are responding to by launching holiday promotions earlier in the season. Black Thursday is a prime example: Many retail customers are planning to be open on Thanksgiving to get an earlier start on the holiday shopping season.”

The earlier you begin to plan your holiday sales season, the smoother it generally goes. Melanie Nuce, vice president of apparel and general merchandise, GS1 US, says that you should start about six to eight months out from the holiday season from a supply chain planning perspective. She also notes, “Most retailers need a 15-day ramp-up when bringing on holiday help. Since it takes a couple of weeks to onboard someone and train them, you have to have a strategy to account for the slowdown in volume and operations to bring on those new team members. Have that plan in place well ahead of the time you actually see the increase in demand. Staffing is critical, so know when your busiest time is coming and have those people hired. For the holidays, it should be before Nov. 1.”

“Companies need to plan ahead and spend the time reviewing their past sales data during the holiday seasons, and create a sales plan with an inventory strategy,” agrees Nick D’Alessio, global practice leader of retail, Zebra Technologies. “Responding to a sudden demand increase in the middle of the holiday season can be devastating, especially when out-of-stocks occur. This can create lost sales/revenue that you cannot recoup. If the products are commodities, do you have second source suppliers that you can diversify and spread your demand across? If they are specialty items, have you negotiated supply allocation replenishment terms with your suppliers? The point here is to start planning before the holiday season arrives—not during.”

Then again, premature planning can be inefficient, too, in terms of rework and lost opportunities, unless the plan is constantly re-evaluated as the holidays draw near. While every market varies, Jonathan Scheele, vice president of supply chain solutions, Ingram Micro Mobility, suggests, “Preparations for Q4 should be thought out at the beginning of Q3 and well into implementation by the end of Q3. This plan should include determination of anticipated holiday shelf-keeping unit (SKU) proliferation by model, channel and region, and developed marketing concepts and packaging designs for holiday promotions. Another consideration is that pallet displays, end caps and promotional packaging may vary between direct-to-consumer SKUs and retail SKUs, and even between retailers. Delaying final customization of finished goods allows a company to leverage the advantages of both push and pull supply chain models. It allows for aggregation of demand for common component SKUs at the manufacturing phase, giving more scale to the manufacturing process.

“Product postponement also minimizes labor and materials requirements for final configuration until there is firm demand from the customer. For this reason, delayed differentiation plays an important role in optimizing a supply chain, even during the frenzy of the holiday season. Conversely, abandonment or disregard for effective product differentiation planning can lead to packaging rework either at the manufacturing facility, third-party logistics partner or distribution center. This creates unnecessary waste in materials, labor and time, not to mention potential lost sales if the product isn’t available on the shelf.”

Know Your Market, Customers and Suppliers

It’s imperative to know both your market and your customer to best predict demand, so you must conduct not only historical, but also market research to produce a forecast as accurately as possible. To complicate matters, if you are an omni-channel retailer, you must be able to generate an even broader forecast across similar, yet differing demographics. Luckily, there are now a variety of tools to help hone and simplify that process.

“If you have effective inventory planning, you can sense demand,” Nuce says. “If you have demand signal management capability, then you can track [sales] based on past trends or on your current pipeline. Social data, or big data, is also important. Being able to integrate social feedback from grassroots consumer components back into your larger community can lead to greater success.”

Nathalie Regniers, industry and solution strategy director for supply chain management and product lifecycle management, Infor, also mentions the significance of historical data: “Within the demand planning process, historic profiles should be captured to understand uplift and lag behaviors. When holidays fall on different dates, companies should weight pre- and post-buying behaviors to accurately assign the uplift or lag to the correct dates. When holidays fall on the same date every year, such as Christmas, it’s important to use a learning forecast engine that adapts to changes in seasonality and growth.” In line with that reasoning, to generate better forecast results, adjust Black Friday and Cyber Monday sales from years prior in order to fully take advantage of that data.

While demand forecasting is essential to a successful holiday retail program, even more important is supply chain visibility in order to actually meet those plans, even when unforeseen events occur. In that case, it’s always best to have a back-up plan. According to Tamara Saucier, vice president of industry, retail solutions, GT Nexus, “End-to-end supply chain visibility allows leading companies to prepare and respond to holiday market demands. Deeper visibility further back into the supply chain allows logistics organizations to properly source and schedule cost-right delivery solutions. New levels of product and cost visibility also provide opportunities for optimizing carrier selection, route selection and mode selection. Flexibility and responsiveness are as strategic as the cost drivers.”

Alavi additionally stresses the priority of logistics and shipping—after all, what good does having the right amount of inventory in stock do if it doesn’t arrive in time? “Before the holiday season begins, retailers predict which items will be the most popular. That’s when it’s beneficial for brands to work with their transportation providers to discuss freight shipments, and if there’s a demand, the need for expedited shipping. It’s beneficial for retailers to work with suppliers that have flexible supply chain operations. For example, integrated transportation providers that have the flexibility to upgrade shipments from deferred air to express air are critical. Providing flexibility for guaranteed expedited shipping options with early delivery times to stock the stores before they open to the public is also important.”

Online… All the Time

To be omni-channel is to be channel-less because the shopping experience for a brand should be comparable no matter what channel is used. While it may seem counterintuitive, it’s consistency that shoppers are seeking—whether it be a brick-and-mortar store, an online shopping portal, an iPhone app, social media or any combination of channels—and that is what they expect. Is there room for different promotions, packages and options? Absolutely. Is there room for a discrepancy in customer service, price ranges, or receipt or availability of the product? Not so much.

When accommodating various channels, “It may be a real challenge to decide what your product offering will be and how it will be offered, and you may have to spend a lot of time doing value-added services, such as repacking, reticketing, removing prices for gift items and gift wrapping to accommodate that offering. [That’s why] retailers should consider that there is a big difference in merchandising in the store—is the item on a hanger? Is it a package of multiples? Many companies separate these two things, but they need to look at the holiday season from a big picture and build execution plans that vary by channel,” Nuce concurs

Again, you must remember who your customers are and what they expect, and more importantly, they have the ability to search for something better online or on their mobile device, and they will. In contrast, the more chances you have to connect with each consumer on a personal level, the better. And that means trying to expand your reach to physical locations and an online presence in the present-day competitive marketplace. It also means that you must not only gather statistics, but also analyze and act on them to establish the best connection.

“One of the most innovative channels that many retailers overlook is the emerging fourth channel of retail—social media. Integrating a social media strategy into your holiday sales planning can provide additional visibility for free,” D’Alessio muses. “Additionally, training sales associates looking for upsell opportunities can increase the size of the shopping cart as accessories and adjacent merchandise are often forgotten at the point of purchase. Whether it’s batteries or a matching shirt to go with that new pair of pants, the power of suggestive selling is huge.”

Although omni-channel retail offers major opportunities, it also spurs major competition, and in some cases, you may find yourself, David, up against Goliath. Saucier cautions, “Amazon is already rapidly moving towards same-day delivery by building an expansive network of distribution centers across the country. They’ve turned supply chain and speed of delivery into a competitive advantage. As a result, retailers must be prepared to match this type of delivery performance or provide clear differentiation to compete. When the supply chain is capable of shipping direct to consumer or direct to any channel within days, there’s more time to adjust inventory and orders in response to sudden demand increases. The combination of inventory visibility and rapid delivery are essential. Retailers have to know where all inventory resides in factories, warehouses and in transit. With that data in hand, decisions can be made to rapidly shift orders to better match spikes in demand.”

Nuce agrees that omni-channel retailing requires effective trading partner collaboration to establish better end-to-end visibility—“meaning knowing and understanding inventory in your own network as well as your partner network. Real-time inventory visibility needs to extend beyond the four walls of your store. Be able to answer what do I have and what does my network of providers have? Taking this further, you should also focus on distributed order management. This means you have a strategy for how you can fulfill the order from where it can best be fulfilled.”

She says that many stores are fulfilling orders on premise, directly and effectively leveraging their assets and inventory. In this scenario, the consumer receives product in one to two days instead of four, which is how long the order may take when being shipped from a warehouse. In the compressed holiday retail cycle, that can seem like an eternity.

Be Ready to Stock Some Stockings

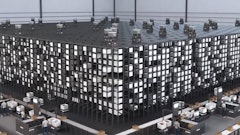

OK, holiday orders are coming in fast and heavy. Now how do you most accurately, efficiently and cost-effectively stuff those stockings? For starters, to speed up order fulfillment—and thus delivery—it is best to not only have the correct product available, but also be able to easily and rapidly locate it. It’s a simple concept, yet requires a lot of time and effort to implement. Fortunately, solutions abound.

One such solution is the use of radio frequency identification (RFID) to track and locate product, which improves product availability (because it’s not getting lost or misplaced) and increases inventory accuracy (because it’s difficult to confuse product using embedded tags or codes), resulting in a higher level of customer satisfaction (because customers are receiving the right product on time in the agreed-upon location). Nuce says, “Electronic product code-enabled, item-level RFID is key to ongoing accuracy. If you’re engaging in an item-level RFID program, you make a commitment to knowing what you have and where it is at all times. It all goes back to enterprise-wide visibility. Inventory also means not only what we have now, but also what we expect, and what’s available through suppliers and partners to support contingencies. Especially if you are on the retailer side, analytics become very important—at the store level and at the supply chain level. All inventory should come with a plan for how to move it.”

Additionally, Chris Arnold, vice president of operations and solutions development, Intelligrated, advises, “Take advantage of fulfillment execution software to optimize inventory, orders, picking, packing, routing and shipping. Light- and voice-directed picking technologies also speed the order fulfillment process and maximize accuracy.” Bruce Stubbs of Intermec echoes his sentiment: “Paper-based methods of fulfillment are inaccurate, less productive and typically very difficult to train temporary workers on. Voice technology is especially effective in getting new workers trained and productive in a matter of hours vs. days or weeks.”

Another critical component to getting product out the door is having an organized and prepared warehouse, distribution center (DC), etc. According to Arnold, “If a critical area of your DC goes down, have a back-up plan, or better yet, plans. Be prepared to divert product around non-functioning areas while the maintenance team resolves the issue, and ensure associates on site are well-versed in appropriate action in the event of an emergency. Facilities should be well-staffed with maintenance personnel, and in the event of an issue that can’t be resolved by on-site resources, be sure to have [equipment] suppliers’ technical support numbers available” to help Santa’s workshop run smoothly at maximum uptime. This means performing preventive maintenance weekly, and conducting general system assessments to notify operators of any repairs, replacements or upgrades necessary to keep systems running at peak efficiency.

A Happy Ending

“This year, more than ever, holiday retail is all about delivering to the consumer with speed, accuracy and flexibility,” according to Saucier. She offers a few more tips for avoiding customer disappointment this holiday season:

- Know sales trends and be able to respond. Understand customer tastes and buying patterns, and align the back end of the business to ensure products can be delivered according to the needs and wants of the consumer.

- Don’t make promises you can’t keep. A broken promise is more harmful than a promise not given. Know the limits of your customers, but more importantly, know the limits of your supply chain. Do you have the ability to ship directly to consumers in three days? Is same-day delivery possible given the existing logistics architecture? Do you have inventory visibility across all channels of the business? If retailers can’t answer these questions with certainty, then delivery offers and promises need to be scaled back.

- Enable full assortment availability to your customer. If you can provide real availability with confidence, the consumer will remember. But again, this requires visibility.

The Holiday Dossier

Earlier this year, UPS worked with comScore to conduct the UPS Pulse of the Online Shopper study, asking online shoppers about their purchasing experiences. Since the holiday peak can account for up to 70 percent of retailers’ annual sales, according to Melanie Alavi of UPS Retail, the following statistics and tips can go far in making the most of the season:

Communicate Delivery Dates

The study’s respondents indicated that the second most important factor for closing a holiday deal—after free shipping—was providing details about shipping costs and delivery timing during checkout. Furthermore, if fulfillment orders are delayed due to the holiday rush, it’s beneficial for retailers to communicate those delays and accommodate consumers with faster shipping options.

Optimize All Channels

As a good practice, retailers should provide the best possible browsing experience for tablets and smartphones to increase conversion rates via those devices. The report also revealed that:

- Nearly seven out of 10 consumers said they prefer to access their favorite retailer via digital and social channels.

- 50 percent of consumers who use a smartphone make purchases on a smartphone.

- 47 percent want a coupon or promotion sent to their smartphone because the retailer knows they are in the store or nearby.

- 60 percent of consumers who use a tablet make purchases on a tablet.

- 41 percent spend more on mobile websites than online, while 26 percent spend more on mobile apps than online.

Make Returns Policies Transparent

Retailers claim the customer experience no longer ends at checkout. Returns play a significant role in repeat customers, brand loyalty and additional sales. According to the study:

- Returns are on the rise as 62 percent of consumers said they returned an item bought online in 2013 compared to 51 percent in 2012.

- 66 percent of online shoppers said they review a retailer’s return policy before making a purchase compared to 63 percent in 2012.

- 74 percent said a hassle-free returns policy impacts their decision to shop with a retailer for the first time.

- 64 percent said they would recommend a retailer to a friend if that retailer offers a hassle-free returns policy.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)