Advances in supply chain management (SCM) technology have often been slow to come to the retail party. But retailers like Wal-Mart Stores Inc. changed that. They demonstrated that investments in SCM can create a differentiator. Still, the question remains: What persuaded retailers like Wal-Mart to invest in SCM? And what changed in the last decade to drive SCM investments?

A lot has changed, in fact. In these difficult times, the retail industry attempted to conduct business more strategically to bring fresh focus to its transportation and warehousing processes. And as markets get larger, interestingly, there is a return of the drive towards the regional warehousing concept vs. relying on a single warehousing site to service all customers and locations. Common sense tells us that being closer to the customer helps business respond faster to demand. And with fuel prices continuing to fluctuate and add to costs, operating in areas that help optimize transportation costs is a prime requirement.

It also helps that this network strategy works just fine from an environmental perspective as well. We are increasingly being put to the test with problems related to environmental degradation. Simple solutions such as using the same vehicle and/or equipment that is used to bring products into distribution centers for outbound shipments to stores can make a big difference in better managing transportation costs and reducing asset capacity constraints. The challenge here is to manage the complexity that strategies—such as continuous moves throughout the supply chain—require.

The need is for smart, intelligent systems to help optimize daily decisions for retailers whether it is identifying optimum shipment sizes, automatically selecting the right mode of transport—from rail, truck, air or ocean—or accurately forecasting demand for individual stores. Once organizations are geared with the right tools, cash committed to inventory and other supply chain-related expenses comes down and the risks for excess inventory reduction actions, such as markdowns, are reduced.

SCM systems bring on the value

Intelligent SCM systems address a long and formidable wish list.

- They enable multiple warehouses with a regional focus;

- They enhance response to changing markets by identifying optimum locations for warehouses and suppliers;

- They help improve real-time supply chain visibility;

- They introduce ideas for more efficient fleet and shipment management;

- They help optimize shipment sizes;

- They enable improvements in forecasting of customer and store demand to help increase product turns and sharpen just-in-time inventory management capabilities.

The direct impact of employing SCM tools can be measured in areas such as reduced costs; improved equipment utilization; increased labor utilization and better warehouse space management; along with better inventory visibility and connectivity with key trading partners. The indirect implications of employing these tools can be realized in other important areas such as recruitment, training, costs, rewards and employee retention.

It is reasonable to assume that central to this transformation in warehousing, shipment and inventory management will be a high degree of automation. The good news is that technology continues to improve, making it possible to bring down the cost of implementation permitting an organization to employ multiple types of automation throughout their supply chain network.

Today, we have voice technology; more efficient and accurate ways to manage data entry; the growing use of sensors to monitor product and asset conditions; continued advancements and usage opportunities for bar-coding technologies and RFID; along with GPS that can be deployed for increased visibility throughout the supply chain.

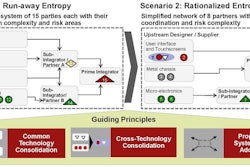

The challenge for retail is to how to best integrate the disparate technologies and systems such as quality management systems (QMS); WMS; transportation management systems (TMS); enterprise resource planning (ERP) systems; learning management systems (LMS); and operating management systems (OMS) to mine data across the enterprise for business intelligence.

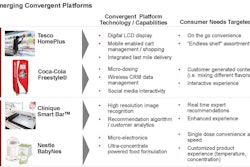

The need for integration in retail is urgent. Retail end customers want to be in stores, they want to be online, and now, they also want to be mobile. These customers are demanding options. They want flexibility in the time their shipment reaches them; they want shipments broken up to reach various destinations; and they want customization of stock-keeping units (SKUs).

Address the challenges and move forward

Meeting these increased customer demands presented additional challenges in the retail sector. Should a retailer fulfill online customer orders from a central warehouse or from a store that is closest to the customer? Should a retailer offer in-store or special event pick-up of orders? How can a retailer best service mobile customers? How can a retailer best manage multiple channels of distribution and effectively compete with online-only competitors?

Retailers must begin to examine next-generation solutions to address these dramatic business changes. It may not always be necessary to take the plunge to build big, complicated systems that large projects require (and which can’t always be scaled back during lean periods or become outdated quickly). SCM software providers continue to make advancements in flexible cloud-based solutions, as many now offer pay-per-use models. While cloud-based SCM solutions may have initially arrived late to the party, they are anticipated to become more attractive in the near future; and may provide more viable options in the transportation and warehousing areas.

In addition, another trend may actually signify a more comprehensive solution to future needs as retailers may find it more attractive to have all the core transportation, warehousing and labor management tools integrated into one application. As package applications continue to develop and expand current core functionality and configuration capabilities, the value proposition for solution providers to offer this alternative increases. In addition to being highly configurable and scalable to meet changing needs, these future solutions can offer critical benefits such as a broader solution; faster overall implementation; lowered risk of integration snafus; lowered cost; and faster turnaround. Such solutions will be well received as retailers often have to prioritize which SCM solution to implement at a time vs. being able to employ a more transformational solution that benefits many areas.

Points of interest

How do you know that your business is in need of a partial or complete upgrade? How do you determine if there are additional technologies or integration opportunities that may expand your current capabilities? IT and SCM leaders are answering these questions by either conducting an inventory of existing SCM tools to understand any gaps in critical business functionalities; or enlisting the support of a strategic business partner to complete a comprehensive technology assessment. Depending on your unique situation, if your core SCM solutions are over five years old, the answer is probably very evident.

Don’t leave money on the table—identify the intelligent, integration capabilities that your business needs and invest wisely.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)