Businesses across the world are in a state of flux. Whether it’s the after-effect of the recent recession or fear of a double-dip, the business landscape has changed forcing companies to examine the way they operate.

In an attempt to increase their competitiveness and improve company-wide efficiency, organizations are turning to management consultancies to overhaul their entire business. But one of the biggest areas for improvement that is often overlooked is the supply chain, and while management consultants are unsurpassed at analyzing overall performance and designing ideal operating structures, the intricacies of the logistics function require specialized attention.

With a multitude of questions, such as how to connect various global or regional suppliers, codifying the weight and quantity of hundreds or thousands of small and large parts for shipment, developing the build plan for the production line, understanding any opportunities for consolidation in various geographies and creating staging facilities for ocean, air and ground shipments, it’s easy to see the need for a specialist to achieve maximum profitability. But creating a detailed strategy is only the beginning. A supply chain expert must turn an idealized vision into a reality, managing the entire process efficiently, within strict time scales and most importantly, in a cost effective manner.

So, how do companies do this? How do they reengineer their entire global supply chain – which often accounts for a third of their business – building on what they already have and what they’re already doing well, while implementing smart suggestions from leaders in consulting? This article discusses the trialed and proven steps in that process.

Rocket science: Keep it simple stupid

Have you heard the phrase, “the simplest solution is often the best”? Well that’s exactly what logistics is about—applying commonsense solutions to complex problems. Whether it’s a fashion business or an industrial parts manufacturer, thousands of businesses have been able to transform their entire organization by making simple changes to their supply chain.

Take for example one of the world’s leading aerospace manufacturers, a CEVA customer, which was able to revamp its entire business by following easy to execute solutions tailored specifically to its needs.

Using best practice from the automotive sector, CEVA created a bespoke logistics solution that kept efficiency paramount, while ensuring that affordability was at the core of every element of operations.

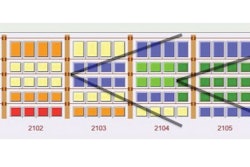

The client, which was responsible for the delivery of a completely manufactured aircraft, created the end product based on various smaller components constructed by its partners. This large supply base, located across various geographies, meant that a material management structure and flow needed to be devised and implemented to ensure synchronous assembly and integration.

Leveraging our existing origin network, CEVA was able to coordinate and support suppliers by providing international and domestic movements to the customer’s inbound logistics center. From there, we developed ways to get the material to the production line in the most appropriate way—releasing material at exactly the right time and with the desired quantity needed. Real time visibility also means that we are able to oversee the entire operation, and that our customer is able to allocate shipments against in-transit inventory.

This solution ensures that all pieces of the complex puzzle work seamlessly, so that our customer is able to deliver to its high standard, all while reducing premium freight and warehousing costs for the company.

Change starts here

For any organization, there are various factors that need to be prevalent to bring about this type of change; these basic principles are required for the successful execution of any supply chain transformation project.

A willingness to change that is embedded within the organizational culture is extremely important, as is an understanding of the current business successes and desired outcomes of the project. However, from our experience the most crucial aspect is progressive leadership.

By analyzing industry trends, and from the work we’ve undertaken, it’s evident that companies who lead in supply chain performance display distinct characteristics compared to average performers. While those who are considered “best in class” are focused on the strategic management of the supply chain, average performers are more focused on tactical elements of their logistics activities. For instance, a rigid focus on individual rates as opposed to the total delivered cost can lead to inefficiencies in the supply chain and fragmented processes with incremental improvement.

Over the past 18 months, these efficiencies have been highlighted due to the financial pressures brought about by the recession. This has placed a greater importance on supply chain management and resulted in senior leadership being more engaged in the process. This newfound eagerness to address the supply chain should be welcomed but global supply chains are extremely complex, so any attempt at innovation must be successful in the first instance.

One company that has benefited from a change in organizational mentality is a leading technology provider that wanted to break away from its “business as usual” approach to enhance its competitiveness in a consumer-driven market that is built upon product innovation – a sector where overall success is based on the timing of product releases and effectiveness of distribution.

There was an additional and underlying desire to be seen as innovative against its competitors, specifically its biggest rival who was being applauded for its supply chain successes by industry commentators. These factors contributed to the motivation that drove the customer to seek change within its organization.

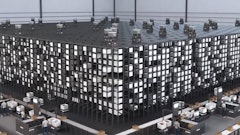

To meet this need and improve the delivery of millions of units of hardware and software products directly to consumers, as well as to distributor and retail channels, CEVA developed an entirely new, flexible and innovative supply chain solution.

Understanding that the customer’s industry is characterized by complex challenges driven by high seasonal fluctuations in market demand, increased SKU profiles and market channels, and cost pressure from competition, CEVA was able to fulfill the company’s changing needs. The logistics strategy was implemented without affecting current levels of service and worked to support the forecasting, planning, manufacturing, order management, distribution and logistics of the division’s products.

As a result, the company was able to balance inventories for shelf availability while increasing profitability in their product lines through a highly flexible and efficient supply chain. Oh, and it also received peer recognition for its newly redesigned logistics functions.

Finding the way: a roadmap to transformation

One of the biggest challenges a company who wants to bring about change faces is where to start. The idea of transforming a multimillion-dollar unit within any organization can be a daunting task—especially when placed under financial pressures.

Once senior leadership is on board with the proposed transformation, and there is a willingness to learn and adapt within the organization, a change sponsor or manager must be appointed. This is someone who has the time, authority and motivation to oversee the change – from strategy to implementation. This person, usually a member of the senior management team, will support, communicate and monitor progress in order to ensure that the project is being completed as planned.

Priorities must then be established based upon the business case – elements such as service, cost and ultimate objectives need to be determined to ensure that any alterations to the management of the logistics are linked to bottom-line performance. These priorities must then be sequenced in order to drive maximum operational and cost benefits as quickly as possible. In tandem with this, a process review and opportunity assessment needs to be undertaken to define the specific areas that require attention and would benefit from improvement.

Finally, a staged emphasis on agreed upon objectives is needed to measure results. This course of action will work to ensure that the transformation project works seamlessly, and toward the agreed upon outcomes.

A company that has been able to utilize this approach and bring about significant savings is an industrial product manufacturer, with more than $20 billion in annual revenue.

From a detailed analysis based on twelve months of customer orders, benchmarking activity and establishing order-to-delivery, cycle time and quality metrics, it was clear that there were inefficiencies in the supply chain—specifically in the movement of product from the U.S. to more than 15 countries in Asia-Pacific, a region that was experiencing significant growth.

Understanding the current state of operations allowed CEVA to develop a picture of the desired state, which for this customer meant decreasing the 32-day origin to destination cycle time. Further analysis also illustrated that this process had been deteriorating over time.

With only 14 days of that being allocated to transit, we understood that processes needed to be improved, specifically in the area of visibility so we could see when product was being release from the supplier, when they were moving and how we could synchronize that with the shipping schedules of the steamship lines.

The result was a supply chain inventory reduction of more than $4.5 million and an overall origin to destination cycle time of 26 days, a six-day improvement.

By utilizing supply chain management and logistics as an area for improvement, businesses from all sectors are reaping the benefits of change – from increased cost savings and a streamlined time-to-market operating structure to a more cohesive and flexible business model.

Understanding that your business requires change is the first, and often hardest, step in the process that will eventually lead to a stronger business. Following the above-mentioned steps will help with development and allow any company to better understand where it currently is, and ultimately where it wants to be.

Remember, improvement is out there for those who choose to seek it – and in most cases, it’s often the simplest solution that is the best.

Kim Wertheimer is Executive Vice President, Strategic Development for CEVA. He is based in Houston, Texas. For more information, visit www.cevalogistics.com.