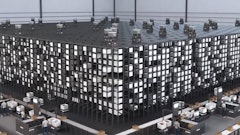

Elk Grove Village, Ill.—June 6, 2012—Material handling systems provider Wynright Corp. introduced a hybrid materials handling system for warehouse/distribution center eFulfillment that integrates pick-to-light and put-to-voice technologies into a single offering.

The patent-pending hybrid system allows pickers to fill multiple orders at the same time rather than having to pick and put each order sequentially. Combining order fulfillment this way can help organizations realize up to a 25 percent increase in picking rates per hour—the equivalent of adding an extra person to an eight-hour shift.

“Pick-to-light and put-to-voice systems have been around for several years and each type independently has its strengths and weaknesses,” said Zane Daggett, General Manager, Selection Division at Wynright Corp. “This is the first instance, however, where the two have been combined into an integrated system. While it seems simple, even obvious on the surface, it takes a lot of expertise in materials handling and these technologies specifically to make it work effectively.”

In a standard warehouse or distribution center, pickers receive a single order, then pick the individual components from bins around the facility and put them in the tote for that order. For popular items, pickers may go to the same bin a dozen or more times each day. With Wynright’s hybrid light/sound system, orders can easily be grouped together. The light system directs the picker to all the required bin locations and shows the aggregate quantity of items that should be picked for all the orders the picker is currently handling. The voice system directs individual order quantities into which totes each product should be placed—saving time and increasing productivity. In addition, the hybrid light/sound system can be easily integrated into all standard warehouse management systems (WMS) further automating the process.

Wynright designed the hybrid light/sound system to be very flexible to adjust to the capabilities of the workforce. For example, new employees may only be assigned two simultaneous orders, while experienced pickers may be responsible for a dozen or more orders on a single run. It can also be adjusted to accommodate faster picking in areas where lights are not available, such as end caps.

“This new system answers a growing need among large and mid-size enterprises (LMEs) that are being challenged to manage ever-higher volumes of smaller orders from online customers,” said Kevin Ambrose, Chief Executive Officer of Wynright Corp. “It’s a great example of Wynright’s solutions-based approach to materials handling.”

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)