What does it take to make a marriage work? Common interests and values of the partners represent a good beginning, along with good chemistry. But it takes more than common interests and chemistry to develop and sustain a relationship. It also takes a mature approach by each person, along with an appreciation of building something together that is bigger than the sum of the two individuals. Business works the same way.

Common Interests and Mutual Attraction

Traditional supply chain interests center around cost, quality and delivery. These interests intersect neatly with sustainability in our real-world examples of supply chain blocking and tackling improvement initiatives, including:

Much has been made of the confluence between supply chain and sustainability around cost. Notable published successes include Pepsico's annual reductions in unit energy, fuel and water consumption per bottle of soda produced and delivered over several years, benefiting both unit costs and environmental performance. These results were achieved by addressing both manufacturing process and product packaging. Fuel costs, in particular, were reduced by reducing packaging weight. With most energy and other inputs consumed in the supply chain for many companies, a natural attraction and alliance coalesced around achieving cost savings.

Less obvious is the advantageous relationship between environmental performance and quality. Virtually every "cost of quality," whether product- or process-related, also represents "cost of carbon." Products that do not meet shipping specifications require extra energy to make a second time. Manufacturing processes with low yields systematically drive more energy and carbon footprint per delivered unit of product. Working together with a client in the building products industry utilizing "wet process" manufacturing, for example, we were able to reduce natural gas consumption per unit shipped by 6 percent, largely by increasing production yields. Product quality and durability in use by customers represent yet further opportunities for simultaneous supply chain business and sustainability benefits. Returned product and repairs represent profit leaks as well as carbon waste. Reducing the frequency of returns through design enhancements and other means has beneficial effects on both measures.

Since returns are rarely reduced to nothing, shortening return/repair loops by placing triage and first-level repair centers closer to customers, as we helped a manufacturer of mobile devices to do, can save transportation-associated carbon footprint and dollar costs, while also increasing customer satisfaction in the speed of response. This also addresses the third traditional supply chain interest: delivery. Delivery performance and cycle times assume a much greater role in optimizing production and distribution networks. Production, inventory and transportation costs enter the equation, along with speed of delivery. Shortening total distance from production through distribution saves fuel and carbon while also speeding up cycle times, illustrating this confluence between these supply chain and sustainability interests and suggesting a likely trend to have both the supply base and production facilities located near served market clusters.

A Mature Approach Drives More Substantial Results

It is clear that supply chain and sustainability have much in common. Lasting marriages need a mature approach by both partners to go beyond initial common interest and chemistry. This mature approach works to transform initial common interests into building a life together, and it must also handle divergence in interests when these inevitably appear. So it goes with business maturity.

The notion of increasing yields, mentioned above, illustrates how we define maturity. The less mature approach examines yield in one factory, while the more mature considers yield across an entire supply chain. Small wonder that this type of end-to-end thinking has more potential to "build a better life." Supply chains with only three tiers have an overall yield of only 86 percent even if each tier has 95 percent yield; at 90 percent individual yield, the overall figure drops to 73 percent! The danger of sub-optimizing lurks behind point fixes. For example, if a factory raises its internal yield by "cherry picking" output from a lower tier of production, this apparent yield improvement is completely offset by yield losses in the lower tier. Overall, supply chain and sustainability are no better off, and the improvement investment is largely wasted. While end-to-end intervention has more potential benefit, it also requires more proactive planning, process underpinning and consistent execution over a longer horizon to realize that potential. The more mature approach to getting both supply chain and sustainability results incorporates these characteristics.

While better yields usually benefit both supply chain and sustainability interests and measures, these can also diverge. Are the yield-related gains in quality and carbon worth the investment to achieve them, and what about possible associated increases in product cost? Not every sustainability or green investment makes supply chain or business sense. Mature approaches incorporate the quality of decision-making processes under these circumstances along with that type of supporting information.

Good decisions depend on integrating partners interests within a broader framework of what is "good for the family" — or what is good for the business. Mature approaches explicitly integrate supply chain and sustainability decisions within the framework of the overall business rather than treating either separately or off to the side as corporate social responsibility. Tradeoffs between business needs are approached explicitly and systematically from a combination of solid quantitative, analytical and strategic perspectives. This, in turn, depends on having good supporting information and metrics as well as an articulated strategy for defining the role of sustainability and supply chain in building and defending competitive advantage. Not only tradeoffs, but also business synergies must be evaluated through the same objective lens. To what extent do more sustainable supply chains become feature-able in promotion efforts, much as "Freshness" and "Made in America" have had their days in the sun as supply chain characteristics? Only a mature approach, with solid information and metrics can answer this question.

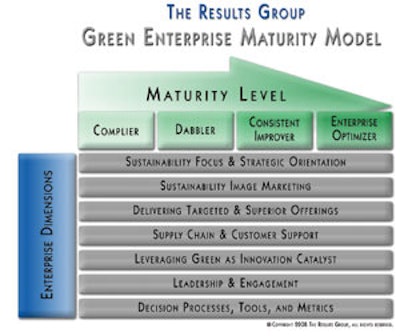

Articulating strategy, decision making and supply chain acumen form several important dimensions of what we call "Green Enterprise Maturity," seen in the figure to the right. Higher levels of maturity represent greater capability to generate and maintain competitive advantage, in this case leveraging both supply- and demand-side opportunities and threats around green and sustainability trends.

We recognize four basic levels of "Green Enterprise Maturity" (see illustration below) in addressing various kinds of opportunity, including our present focus on sustainability. In terms of strategic orientation, "compliers" do not see opportunity, but only burden; thus they do the minimum required. "Dabblers" relate to sustainability as opportunistic, and hence they adopt easy one-off initiatives to defend image and tweak costs lower.

"Consistent improvers" see a spur to getting better, implementing planned and consistent efforts for performance improvement, backed by processes, often in multiple areas of cost reduction, image and sometimes offerings as well. "Enterprise optimizers" see a springboard to dominance, pushing consistent, innovative and strategically integrated end-to-end efforts to develop and extend structural advantages, winning products and positions, growth, and superior performance. Not surprisingly, these latter companies are the boldest in taking advantage of collaborative opportunities across the supply chain and with customers.

A firm's position is best conceptualized as a mosaic of various levels of maturity across the enterprise dimensions shown above. Every firm should know where they stand and make explicit decisions about where to invest for greater maturity and better business results, realizing that it is generally not possible to reach the highest maturity on every dimension.

Will this Marriage Last?

Supply chain and sustainability have embarked on a marriage with both honeymoon and rocky patches. The honeymoon has been characterized by picking the easy fruit of obvious waste where interests are completely aligned. Coming decisions will get harder, bringing rocks. For example, do we continue to drive for smaller lot sizes in the spirit of Lean manufacturing or go for full trucks in the spirit of sustainability? More rocks come from reductions in energy prices that tend to drive a wedge between perceived short- and longer-term consequences.

Moving beyond this rocky honeymoon, the marriage will last in companies where both supply chain and sustainability:

In short, a good marriage of supply chain and sustainability will result in better business and greater return on investment.

Common Interests and Mutual Attraction

Traditional supply chain interests center around cost, quality and delivery. These interests intersect neatly with sustainability in our real-world examples of supply chain blocking and tackling improvement initiatives, including:

- Reducing package size, weight and expense

- Increasing production yields

- Cutting product returns and repairs

- Optimizing production and distribution networks

Much has been made of the confluence between supply chain and sustainability around cost. Notable published successes include Pepsico's annual reductions in unit energy, fuel and water consumption per bottle of soda produced and delivered over several years, benefiting both unit costs and environmental performance. These results were achieved by addressing both manufacturing process and product packaging. Fuel costs, in particular, were reduced by reducing packaging weight. With most energy and other inputs consumed in the supply chain for many companies, a natural attraction and alliance coalesced around achieving cost savings.

Less obvious is the advantageous relationship between environmental performance and quality. Virtually every "cost of quality," whether product- or process-related, also represents "cost of carbon." Products that do not meet shipping specifications require extra energy to make a second time. Manufacturing processes with low yields systematically drive more energy and carbon footprint per delivered unit of product. Working together with a client in the building products industry utilizing "wet process" manufacturing, for example, we were able to reduce natural gas consumption per unit shipped by 6 percent, largely by increasing production yields. Product quality and durability in use by customers represent yet further opportunities for simultaneous supply chain business and sustainability benefits. Returned product and repairs represent profit leaks as well as carbon waste. Reducing the frequency of returns through design enhancements and other means has beneficial effects on both measures.

Since returns are rarely reduced to nothing, shortening return/repair loops by placing triage and first-level repair centers closer to customers, as we helped a manufacturer of mobile devices to do, can save transportation-associated carbon footprint and dollar costs, while also increasing customer satisfaction in the speed of response. This also addresses the third traditional supply chain interest: delivery. Delivery performance and cycle times assume a much greater role in optimizing production and distribution networks. Production, inventory and transportation costs enter the equation, along with speed of delivery. Shortening total distance from production through distribution saves fuel and carbon while also speeding up cycle times, illustrating this confluence between these supply chain and sustainability interests and suggesting a likely trend to have both the supply base and production facilities located near served market clusters.

A Mature Approach Drives More Substantial Results

It is clear that supply chain and sustainability have much in common. Lasting marriages need a mature approach by both partners to go beyond initial common interest and chemistry. This mature approach works to transform initial common interests into building a life together, and it must also handle divergence in interests when these inevitably appear. So it goes with business maturity.

The notion of increasing yields, mentioned above, illustrates how we define maturity. The less mature approach examines yield in one factory, while the more mature considers yield across an entire supply chain. Small wonder that this type of end-to-end thinking has more potential to "build a better life." Supply chains with only three tiers have an overall yield of only 86 percent even if each tier has 95 percent yield; at 90 percent individual yield, the overall figure drops to 73 percent! The danger of sub-optimizing lurks behind point fixes. For example, if a factory raises its internal yield by "cherry picking" output from a lower tier of production, this apparent yield improvement is completely offset by yield losses in the lower tier. Overall, supply chain and sustainability are no better off, and the improvement investment is largely wasted. While end-to-end intervention has more potential benefit, it also requires more proactive planning, process underpinning and consistent execution over a longer horizon to realize that potential. The more mature approach to getting both supply chain and sustainability results incorporates these characteristics.

While better yields usually benefit both supply chain and sustainability interests and measures, these can also diverge. Are the yield-related gains in quality and carbon worth the investment to achieve them, and what about possible associated increases in product cost? Not every sustainability or green investment makes supply chain or business sense. Mature approaches incorporate the quality of decision-making processes under these circumstances along with that type of supporting information.

Good decisions depend on integrating partners interests within a broader framework of what is "good for the family" — or what is good for the business. Mature approaches explicitly integrate supply chain and sustainability decisions within the framework of the overall business rather than treating either separately or off to the side as corporate social responsibility. Tradeoffs between business needs are approached explicitly and systematically from a combination of solid quantitative, analytical and strategic perspectives. This, in turn, depends on having good supporting information and metrics as well as an articulated strategy for defining the role of sustainability and supply chain in building and defending competitive advantage. Not only tradeoffs, but also business synergies must be evaluated through the same objective lens. To what extent do more sustainable supply chains become feature-able in promotion efforts, much as "Freshness" and "Made in America" have had their days in the sun as supply chain characteristics? Only a mature approach, with solid information and metrics can answer this question.

Articulating strategy, decision making and supply chain acumen form several important dimensions of what we call "Green Enterprise Maturity," seen in the figure to the right. Higher levels of maturity represent greater capability to generate and maintain competitive advantage, in this case leveraging both supply- and demand-side opportunities and threats around green and sustainability trends.

We recognize four basic levels of "Green Enterprise Maturity" (see illustration below) in addressing various kinds of opportunity, including our present focus on sustainability. In terms of strategic orientation, "compliers" do not see opportunity, but only burden; thus they do the minimum required. "Dabblers" relate to sustainability as opportunistic, and hence they adopt easy one-off initiatives to defend image and tweak costs lower.

"Consistent improvers" see a spur to getting better, implementing planned and consistent efforts for performance improvement, backed by processes, often in multiple areas of cost reduction, image and sometimes offerings as well. "Enterprise optimizers" see a springboard to dominance, pushing consistent, innovative and strategically integrated end-to-end efforts to develop and extend structural advantages, winning products and positions, growth, and superior performance. Not surprisingly, these latter companies are the boldest in taking advantage of collaborative opportunities across the supply chain and with customers.

A firm's position is best conceptualized as a mosaic of various levels of maturity across the enterprise dimensions shown above. Every firm should know where they stand and make explicit decisions about where to invest for greater maturity and better business results, realizing that it is generally not possible to reach the highest maturity on every dimension.

Will this Marriage Last?

Supply chain and sustainability have embarked on a marriage with both honeymoon and rocky patches. The honeymoon has been characterized by picking the easy fruit of obvious waste where interests are completely aligned. Coming decisions will get harder, bringing rocks. For example, do we continue to drive for smaller lot sizes in the spirit of Lean manufacturing or go for full trucks in the spirit of sustainability? More rocks come from reductions in energy prices that tend to drive a wedge between perceived short- and longer-term consequences.

Moving beyond this rocky honeymoon, the marriage will last in companies where both supply chain and sustainability:

- Become or remain important in the bigger picture of strategic competitive advantage;

- Are integrated, in name and in practice, with one another and with core business processes;

- Contribute to higher levels of enterprise maturity; and,

- Incorporate end-to-end thinking, proactive planning and process development, consistent execution and realistic business decisions into everyday operation of the business.

In short, a good marriage of supply chain and sustainability will result in better business and greater return on investment.