The greatest risks to your supply chain are your choices—especially how you treat your supply chain partners. This does not obviate doing risk assessment exercises and trying to anticipate other sorts of supply chain disruptions, yet too many companies underestimate how many company misfortunes result from getting exactly what they asked for.

Here are the three most common risks that companies create for themselves often without realizing, illustrated with examples from the automotive industry.

1. Perverse Incentives

You get what you pay for—and that isn’t always a good thing. Take the example of Takata airbags. Originally a manufacturer of seatbelts, Takata’s fortunes rose with those of Honda and other Japanese car manufacturers in the 1960s and 1970s. As the years went on, Takata’s customers exerted tremendous pressure to cut costs. The one substance everyone avoided in airbags was ammonium nitrate—a tenth of the cost, but inherently unstable. Takata started using it in 2001. The result is the largest and most complex automotive recall in history. Make sure you understand the cost structure for key supplier inputs, be realistic about expectations and don’t go along with something too good to be true until you take the time to understand it.

2. Systemic Failures

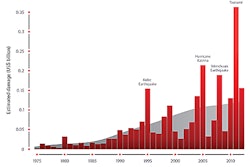

It is easy to armchair quarterback Takata putting a small bomb in place of airbags in one in five cars in the U.S.—a total of 60 million airbags in over two dozen brands. But this is like blaming your favorite child for being caught with his hand in the cookie jar—sure he did it, but his older siblings put him up to it. The huge asymmetry in power between automotive suppliers and manufacturers is embedded in industry practices, as indicated by the growth in automotive recalls over the past two decades. Renault refused to buy the Takata airbags without clear-cut evidence of the safety of ammonium nitrate and this led to Takata’s European operations finding an alternative substance. Be sure to set strategic performance goals and empower key people to pursue those goals even at the expense of short-term profits.

To read the full story, please click here.