Midland, Mich.—Oct. 2, 2014—A pharmaceutical manufacturer makes an unannounced visit to the plant that produces one of its key raw materials, only to find that the plant doesn't even exist. A well-known medical device manufacturer has to initiate a global recall of its drug-eluting stent based on reports of a malfunction of the catheter used to deliver the combination product to the proper position within the blocked artery. Elsewhere, a seemingly insignificant raw material change deep in the supply chain negatively impacts end-product performance, threatening patient safety.

Unfortunately, scenarios like these are happening on a global scale, causing regulatory agencies worldwide to not only generate warning letters and product recalls, but also to enact new standards and regulations focusing on the raw materials used in the manufacture of both medical devices and pharmaceuticals.

Katherine Ulman, global regulatory compliance manager for Dow Corning Corporation’s healthcare industry, said, “While the focus may be on raw materials, it is the original equipment manufacturer (OEM) who is ultimately responsible for ensuring that the materials it employs meet the critical requirements of the applicable regulations.”

This can be especially daunting for manufacturers who are working to develop and commercialize combination products.

Combination Products

According to the U.S. Food and Drug Administration (FDA), a combination product may comprise any combination of a drug, device and/or biological product. The FDA’s Office of Combination Products (OCP) assigns primary regulation of these products based on their primary mode of action (PMOA)—whether they act on the body primarily as a drug, a biologic or a medical device.

Ulman said, “Even if the product is considered primarily a medical device, it will still need to meet requirements related to the drug or biologic that is combined with it. This makes bringing these products to market and ensuring the safety of their supply chains even more challenging.”

The Impact of Supply Chain Integration

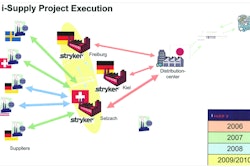

Suppliers with highly integrated supply chains have greater control over raw material changes that could inadvertently impact end-product performance.

“The culprit isn't always a direct change to the material that the manufacturer is buying,” Ulman said. “Sometimes the fault is with a material that goes into that material. An integrated supplier is in a much better position to know about and control those changes than a supplier that purchases many, if not all, of its raw materials from outside suppliers.”

Working with Trusted Suppliers Helps Mitigate Risk

In Ulman’s experience, working with trusted suppliers can help combination product manufacturers reduce their supply chain risks, as well as get their products to market faster with fewer regulatory hassles. She recommends working with suppliers who:

- Have a team of product safety and regulatory compliance experts who are willing to use that knowledge to help their customers navigate the constantly changing global regulatory landscape.

- Provide the appropriate level of regulatory approval support.

- Maintain dedicated, registered healthcare manufacturing facilities.

- Strictly adhere to current good manufacturing practices (cGMPs).

- Operate in accordance with a robust quality management system.

- Provide comprehensive documentation on the traceability of their materials.

- Manufacture and test their materials to ensure that they comply with regulatory requirements in different countries.