Milpitas, Calif.—August 20, 2014—Resilinc Corp., a provider of supply chain resiliency solutions, announced a new version of its Resilinc Conflict Minerals Module, focused on driving down the costs of reporting and increasing supplier participation rates across global supply chains.

Resilinc’s new release features a supplier network-based approach, enabling suppliers to publish CFSI templates once and share them with many customers. Combined with services around supplier onboarding, training and data validation, and automated reasonable assessment tests to pinpoint incorrect responses, this unique supplier network-based approach enables faster categorization and follow-up. Suppliers use the Resilinc platform free of charge to save time and resources, fueling their willingness to participate—and resulting in the highest completion rates and quickest time to compliance for their customers.

Finally, Resilinc features the industry’s first fully automated outbound template generation capability for customers at the product, product family, customer’s customer or corporation level. This unique capability simplifies their efforts in reporting to stakeholders.

Next-Generation Features Lower Compliance Costs and Maximize Results

The Resilinc Conflict Minerals Module addresses these and many other challenges through features, including:

- A network-based approach that enable suppliers to save time and effort by publishing their CFSI template once, then securely share it across their entire customer base simply by approving their access.

- No cost to the supplier since suppliers use the Resilinc platform at no charge.

- Extensive supplier on-boarding and training services in multiple languages and time zones to increase supplier participation rates.

- Fully automated reasonable assessment tests to quickly categorize incorrect responses and facilitate faster follow-up to improve accuracy of the final submission.

- Fully automated Conflict Minerals template creation from consolidated supplier responses that fast-tracks outbound reporting to customers by streamlining the time required to analyze supplier inputs.

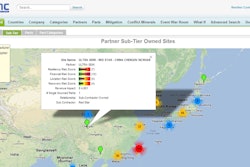

Unique Multi-Tier Mapping Capabilities Help Ensure Compliance

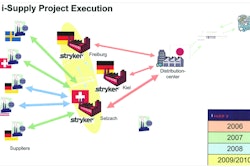

The Resilinc Conflict Minerals Module is fully integrated with a multi-tier supply chain mapping solution, enabling Conflict Minerals compliance efforts to leverage the company’s existing store of information about a supplier’s sub-tier supply chain. Resilinc’s conflict minerals compliance module, paired with the company’s multi-tier supply chain mapping capability, enables companies to follow the letter of the law, and demonstrate their willingness to go above and beyond in complying with the regulatory intent of the Dodd-Frank Act.

Not Just a Compliance Program

Resilinc enables companies to make Conflict Minerals compliance yield real business benefits to the supply chain as well. By mapping their suppliers globally and across multiple tiers, Resilinc’s clients are able to proactively design their supply chain and sourcing networks to reduce exposure to potential risks and capacity bottlenecks in the sub-tier supply chain. In addition, by enabling identification of the component-level composition of 3TG metals at a part number level, Resilinc helps its clients understand how commodity pricing and availability trends impact specific components in their supply chain.

Background

The Securities and Exchange Commission adopted a provision mandated by the Dodd-Frank Wall Street Reform and Consumer Protection Act to require companies to publicly disclose their use of Conflict Minerals that originated in the Democratic Republic of the Congo (DRC) or an adjoining country. Compliance challenges faced by supply chain organizations include resource intensive processes leading to increased costs, low supplier participation rates and data inaccuracy.