Mature organizations across a broad range of industries see product lifecycle management (PLM) as an enterprise strategy in order to drive profitable growth. These organizations have created alignment between their business goals and PLM, and ensure close collaboration with customers, channels, suppliers and service providers during the entire lifecycle of their products. In their internal ecosystem, PLM processes and solutions are not limited to the design and engineering teams, but span planning, sourcing, manufacturing, marketing, logistics and after-sales service teams, too. As a result, these organizations have seen improvements in time to market, design costs, manufacturability and product portfolio management.

The evolution of PLM processes in the high-tech industry has been complicated by the industry’s unique set of attributes, such as the rate of innovation, demand variability, product diversity and complexity, and manufacturing ecosystem complexity. Increasing focus on sustainability and regulatory compliance, and the desire to claim residual value from end-of-life products have created incentives for some members of the industry to address key concepts, such as design for product disassembly, design for refurbishment, and design for remanufacture and recycling.

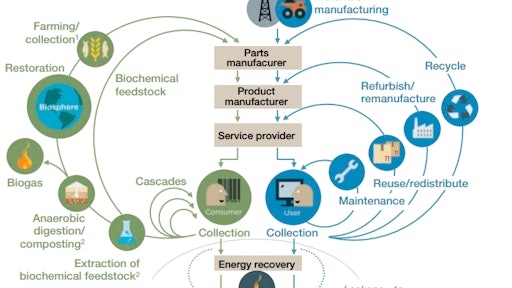

Most industry members, though, see this as a significant challenge, as their engineering and supply chain teams optimized for time to market and lowest production cost, find their current PLM processes and systems inadequate to address the emerging business needs. As a result, recyclability in the high-tech industry is currently limited, and a large portion of electronics does not end up in an optimal waste stream to allow for maximizing residual value. Component distributors like Avnet have created new services to complement their traditional PLM offerings as the high-tech industry evolves from a “make and dispose” linear business model to a hybrid business model (also called partly closed-loop model) that incorporates aspects of sustainability, remanufacturing and recycling.

PLM processes in the high-tech industry are going through a significant evolution to support an enterprise’s twin goals of sustainability and residual value recovery through reuse, remanufacturing and recycling. This evolution involves engineering, supply chain, suppliers, customers, channels and legislating bodies. As an example of the interplay amongst value chain members and PLM processes, consider the following challenges that need to be addressed in order to achieve the twin goals mentioned above:

- Product design would need to incorporate elements like modularity, diagnostics, maintenance, and ease of disassembly and access. When designed for reuse, product performance would need to be stable over multiple lifecycles. Design rules would need to keep recycling processes in mind, while material choices would be impacted by their recyclability. This may impact upfront development costs and would need to be financed through a portion of product residual value. Skillsets in engineering teams would need to evolve, too.

- High-tech industry supply chains are complex, global networks with production and consumption often dispersed across different regions of the world. Smooth bi-directional flow of physical product and digital information would be required to ensure that residual product value can be harvested through reuse, remanufacturing or recycling. Incentives would need to be aligned across the supply chain to ensure that end-of-life products can be routed for remanufacturing or recycling. The role of the channel would evolve away from the linear one-directional value proposition to include reverse logistics and accompanying services.

- PLM systems would need to track product and traceability data across multiple lifecycles in many cases. This data would also need to be shared across multiple members of the interconnected value network in order to support services, such as warranty, diagnostics and repairs.

- When analysis of the economic lifecycle of products includes remanufacturing, reuse or recycling, new business models based on pay-per-use, pay-for-performance, leasing, rental and trade-ins would be possible. These would have to be supported in the supply chain network through new revenue recognition paradigms. Several industries, including segments of the high-tech industry, have successfully transitioned products into service-based business models.

A host of emerging information and manufacturing-related technologies are helping create the foundational infrastructure to support widespread adoption of future PLM and supply chain processes. Internet of things (IoT) technologies, mobility, cloud adoption, big data, analytics, robotics, 3D printing, additive manufacturing, advanced materials and renewable energy technologies are examples of forces converging together to help power sustainable, agile and demand driven bi-directional supply chains. Initiatives such as Industry 4.0 in Europe and the Smart Manufacturing Leadership Coalition (SMLC) in the U.S are attempting to leverage this convergence throughout manufacturing and supply chain.

As PLM and supply chain processes evolve in the high-tech industry in pursuit of sustainability, recycling and residual value capture, leading organizations are investing significant efforts in looking at their design and engineering processes in preparation for future circular economic and supply chain models. These organizations are also creating competencies (through partners or organically) along the reverse cycle and are moving a portion of their product portfolio from ownership to performance-based revenue models. They see an emerging competitive advantage not only due to consumer preferences in support of circular models, but also due to higher revenue per unit input resource (due to potentially multiple lifecycles of the product). In order to support value creation in circular economic models through endless lifecycles, value networks would be reconfigured and the supply chain organizations across enterprises would evolve in structure and function.

For those who see PLM as a mature concept, the road ahead is exciting and evolving.