Route planning—how to deliver freight for the lowest cost, and in a way that meets the constraints and requirements of the order—has been at the core of transportation management systems (TMS) since I wrote the first one in the late 1980s. In fact, I began developing algorithms to solve the routing problem as early as 1984 or 1985.

While the algorithms improved dramatically since then, the basic concept of route planning did not: Logistics professionals still have to create a large set of transportation options that span all of the possible ways to move the freight, plus allow providers wide latitude in how they structure the options. The algorithm considers all of these possible options, models them as accurately as possible, accounts for constraints (if known in advance) and charges appropriately.

From Simplicity to Flexibility

As the transportation industry grows more complex and more factors weigh on the true cost of a shipment, the need for more sophisticated automation is increasing. In the past, software created simplicity in the routing process so that a manual route planner or a weak TMS could handle it. And that left a lot of money on the table.

But today, with more complexity and more powerful software than ever before, the need for simplicity is replaced with the need for a system to manage pricing flexibility that reflects actual costs. This allows logistics professionals to get very creative about route planning—and I think this is one of the most exciting areas of the transportation industry.

How Poor Routing Planning Loses Money

Simplified routing planning isn’t doing your organization any favors, especially when modern TMS systems and algorithms can manage the complexity and lower your freight spend.

Are you leaving money on the table with your TMS? Let me provide some possibilities.

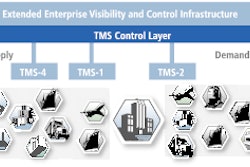

Most companies ask their less-than-truckload (LTL) providers to bid off one tariff. Then they compare discounts and other ancillary issues to select carriers for lanes. This enables simple routing in which a shipment of the right size going in a certain lane gets a pre-determined LTL carrier assigned.

A newer generation TMS, however, allows each carrier to bid very specifically, including off any tariff in which they can be most aggressive. The carriers can set up rates that reflect their costs—as opposed to general assumptions—which allows them to be more aggressive in pricing. Then the TMS can look at each option, figure out if it’s feasible, determine the cost and select the lowest price option.

Very few companies actually use pool distribution. Those that do tend to set up one point per region, and assign freight within a size range and geographic range to that pool point.

A better approach is to allow several possible pool points in every area and have the routing algorithm select which one(s) is appropriate for a load based on the mix of freight. Furthermore, the determination of whether a shipment gets delivered as a stop in transit or on a pool point should not be based on shipment size; it should be based on cost. Depending on the route, a smaller shipment in route is often cheaper to ship as a stop in transit, while a larger shipment out of route is usually cheaper to deliver out of the pool point. When pool distribution is done right, organizations can save significant costs because of it.

The point is that you need to think in terms of flexibility and adding options with your TMS—not the simplification and elimination that are traditionally used when routing freight manually or with a weak TMS.

Defining and Calculating Cost Savings

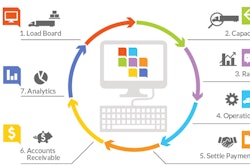

In addition to route planning, another important role of a TMS is defining and calculating cost savings. Today’s TMS systems are making huge strides in savings calculations compared to earlier generations of the software.

Many companies think about cost purely from a decision-making perspective: For every transportation option, there is a savings of one versus another.

But there are more accurate ways of addressing cost that only third-generation TMSs—ones designed in the last several years—can address. Within them exist concepts around base costs and savings of suggested routing versus the base cost. There is also a concept of routes (groups of orders traveling together) and looking at savings over the entire route. Both of these are big, complex and nuanced innovations that are enabling third-generation users to achieve much greater savings than second-generation users. And with the concept of savings versus historical approaches, you can better understand what you would spend moving freight with your old routing approach versus what you actually spent.

Lastly, third-generation TMS products approach savings in terms of marginal costs—not allocated costs—which can generate significantly greater savings. Let’s say you have a load going from Memphis to the Northeast and making a pool stop in the Lancaster, Pennsylvania area. Maybe it’s a great load that still has a little room in it. You also have a shipment going to Augusta, Maine. This could fit on the truck and then the cost of the pool shipment from Lancaster to Augusta would be lower than the cost of Memphis to Augusta. However, when you add the allocated cost of the truckload, the pool shipment is more expensive.

This is faulty, second-generation logic. The allocated cost of the truckload is meaningless! That load is already going and so the Augusta shipment rides for free. The optimization, therefore, needs to look at the marginal cost of adding the shipment to the load and not simplistic allocations.

Get Out of the Dark Ages of Routing

Today’s third-generation TMS optimization engine is far more powerful, flexible and sophisticated than prior generation products—and it’s completely changing the approach to route planning. Now, you can be more creative and drive significant cuts in freight spend compared with older, more rigid TMS products.