In most companies, supply chain is, by definition a shared service. Shared service organizations are set up to support the company’s core business functions. However, where supply chain can put itself at risk is by mistaking what role it plays in the overall strategic direction of the company.

The organizations that make up the company’s core competencies will define the company’s strategic goals. Supply chain leadership should offer expertise on how they can support the core business in achieving these goals as effectively as possible. The nuance is subtle but critical to successfully partnering with the core business functions. There will always be the need to set strategic goals and a vision within any shared service organization. However, the focus with the core business functions should always be on support.

What IT can teach us

The classic example of a shared service is IT. In almost all cases, IT is positioned to make other organizations more effective at achieving the company’s strategic goals. IT does not set the company’s strategic goals. Over the years, some IT organizations began to lose sight of this distinction. It is easy to understand why. As more affordable and powerful technology solutions became available, the role that IT played became more critical. In some companies, the criticality of IT caused IT leadership to challenge their role in the company. Rather than operating as a shared service, IT organizations tried to insert themselves in the core business strategic planning process. IT’s desire to redefine itself in this way demonstrated to the rest of the company that IT had lost sight of its mission. No one questioned that the value of IT had increased. However, the core capabilities of the company continued to see IT as a critical support capability to the business.

The purpose of the IT backdrop is to serve as a cautionary tale to supply chain. Shared service organizations are at a greater risk of being outsourced when they lose sight of their supporting role and begin dictating to the core business functions. Supply chain processes, behavior and attitude should align to operate effectively in a supporting capacity. In some cases, IT organizations were outsourced when they tried to reposition themselves as a core capability. This is not meant to suggest that outsourcing decisions are made solely on a shared service organization’s relationship with the core functions of the business. The point is that it is one of many factors that can contribute to outsourcing. More importantly, it is a risk that supply chain can mitigate.

Define core and support capabilities

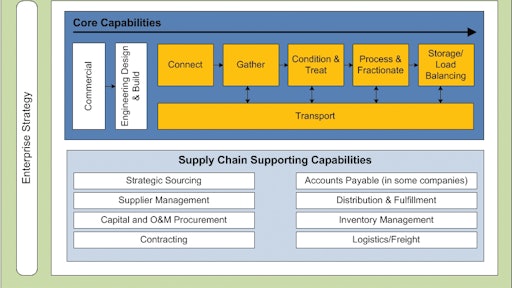

As you begin to assess the mission of supply chain in your company, it’s helpful to define your company’s core capabilities and support capabilities. The core capabilities set the strategic goals for the company and have a direct impact on the company’s gross revenue. All other organizations make up the company’s supporting capabilities. Their mission is to support the core capabilities so that the company as a whole can achieve its goals.

The diagram (see graphic) shows a typical example of the relationship between the core capabilities and supply chain in the oil and gas industry. Both sides are critical to the company’s success. However, the way in which executives view these two categories is very different. It is not uncommon to hear an executive say that the core capabilities are ‘what we do well.’ However, it isn’t to say that the opposite has to be true of the company’s supporting capabilities. This is a critical point to understand when a company is considering whether or not its supporting capabilities should be managed through an outsourcing relationship.

How to operate successfully as a shared service

In the oil and gas industry example, supply chain will operate most effectively as a shared service to the commercial, engineering and operations organizations. It may also support other shared services in the business through strategic sourcing and procurement. The question to answer is: ‘How does supply chain create a culture that allows it to thrive as a shared service and create a competitive advantage?’ To address this, businesses should follow a set of steps to operate a successful shared service.

1. Treat Core Business Functions as Customers—Though the term ‘core capability’ has been used to categorize the organizations that supply chain supports, a more natural way to think of them is as your customers. Shared service organizations that have this perspective will align their service offerings and vision to building this type of relationship. Shifting to this paradigm will allow everything else to fall into place.

2. Practice Humility—This is all about how you approach your customers. Humility isn’t weakness. It demonstrates an awareness of the shared service relationship you have with your customers. It also shows your commitment to the company’s success above and beyond your organization’s own successes.

3. It’s Not Just What You Deliver, It’s How You Deliver It—Supply chain has insight and perspective that its customers may not have. Assume the strategic sourcing team is undergoing a sourcing initiative on safety services. They will uncover information that supply chain’s customers do not have and provide a more complete picture for future buying decisions. This can lead to strategies that will have a positive impact on the company. That said, how this is delivered is as important as what is delivered. Supply chain needs to take this information to its customers and ask for their perspective and direction. The customer’s insight into the category from an engineering and operations perspective can completely change the sourcing strategy. Trying to dictate sourcing decisions will fail and your customers will work around you.

4. Track Your Performance—As a shared service, performance management tracking is critical to demonstrating value. Work with your customers to define metrics that will be used to measure your performance. Don’t define them in a vacuum.

5. Highlight Successes—The answer to the question, ‘If a tree falls in the forest and no one is there to hear it, does it make a sound?’ is No. Don’t presume that your customers are aware of your successes. Take your successes to them. Promote your successes internally at all levels.

6. Pick Your Battles—Some outsourcing may be inevitable as it may align with overall corporate strategies that are driving the core business. An oil and gas company may determine that capital investment in pipeline and processing plants offers a higher ROI than investment in inventory management and distribution capabilities. The lesson here is to fight for the functions in your supply chain organization that have a track record of creating value. At the same time, work with your customers to determine if there is a business case for outsourcing any particular supply chain function. This behavior creates credibility with your customers.

Differentiate your supply chain

Rethinking how your organization interacts with your company’s core functions can change the prognosis for your organization. This shift can become a differentiator amongst your peers and give your company a competitive advantage. There are many companies in the market that are looking for opportunities to run some or all of your supply chain functions. They look at your company’s core functions as potential customers. And you should do the same.